Hot isostatic pressing (hip) is a material processing method, which compresses materials by simultaneously applying high temperature of hundreds to 2000 ℃ and isostatic pressing of dozens to 200 MPa. Argon is the most commonly used pressure medium.

The hot press is very similar to the hip. Milling, forging and extrusion are also suitable for high temperature and high pressure, but not for hot isostatic pressure.

The difference between hip joint and hot pressing

Hip applies isostatic pressure to materials using air pressure, while hot pressure only applies to uniaxial pressure. A fully competent breadwinner

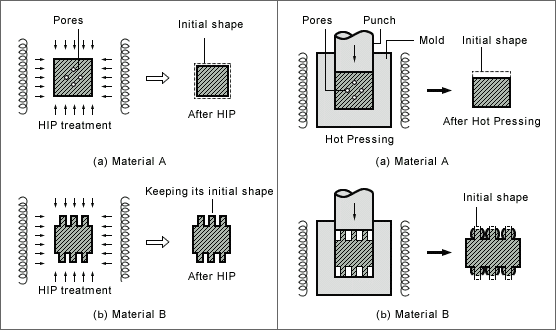

In order to clearly explain the difference between hot isostatic pressing and hot pressing, it is assumed that hot isostatic pressing or hot pressing is applied to material a (metal with holes inside) and material B (metal with uneven ends).

In the case of the hip joint, material a, as shown in Figure 1, will contract to maintain its initial shape until the internal pores disappear and are combined due to diffusion effects. On the other hand, due to the uniform pressure applied to the uneven edge, material B will not change its shape at all.

In the case of hot pressing, material a will also show the same phenomenon as hip, as shown in Figure 2. However, material B cannot maintain its original uneven shape because the pressure only acts on the raised part. Material a and material B will have different final shapes after hot pressing, depending on the shape of the die and punch used. Due to the non-uniformity of mold friction and the limitation of temperature and size in the process of deformation, it may be difficult to manufacture large products and molds at high temperature.

Compared with the hot pressing, the hot isostatic pressing can provide the material shape with little difference from the initial pressure. A material can maintain its initial shape even after changing its shape, and is relatively less limited by the processing of the product. By making full use of these characteristics, hip has been applied in various fields.

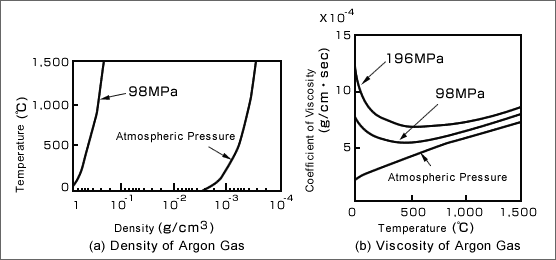

High pressure medium gas (argon)

At 1000 ℃ and 98mpa, argon is likely to cause strong convection due to its low density and viscosity (30% and 15% of water respectively) and high thermal expansion coefficient. Therefore, the heat transfer coefficient of the hot isostatic pressure equipment is higher than that of the common electronic furnace.

Hip application

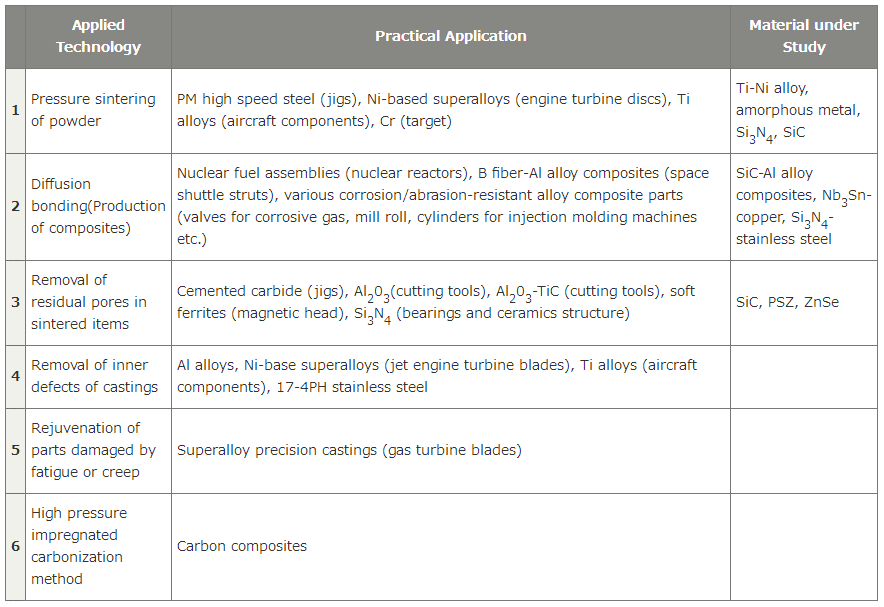

Hip is widely used, as follows:

- Powder pressure sintering

- Diffusion connection of different types of materials

- Remove the residual pores in the sintered parts

- Elimination of internal defects of castings

- Regeneration of parts damaged by fatigue or creep

- High pressure impregnation carbonization

HIP Treatment

Materials need to be treated according to the situation. The most typical methods include “capsule method” and “non capsule method”.

As shown in the figure on the right, “capsule method” is to put the powder or the object formed by the powder into the airtight capsule and empty the capsule before hip replacement.

This “capsule method” can provide high density even for materials that are difficult to be sintered by ordinary sintering technology. Therefore, it is most commonly used in the pressure sintering process of powder materials. It can also be used for diffusion bonding or high pressure impregnation carbonization of various materials.

The following table summarizes the main materials of the capsule free method and hip joint treatment temperature / pressure.

At the same time, if the pores inside the material are isolated and closed, and there is no connection with the surface of the material, these pores may be extruded and eliminated by hot isostatic pressure treatment. On the other hand, even after hip treatment, the open holes connected with the material surface will not be squeezed. Therefore, the material with closed pores can be treated by hot isostatic pressing, which can make the whole material have high compactness.

This material does not require capsule hip treatment, which is known as the “no capsule method.”. It is used to remove the residual pores on the sintered parts, eliminate the internal defects of the castings, and repair the parts damaged due to fatigue or creep.

Hip joint effect

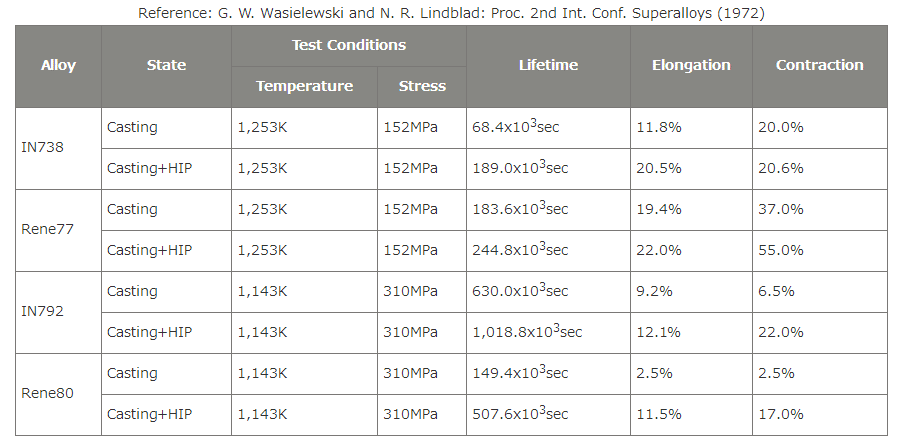

Hot isostatic pressing of castings increases creep rupture life by 1.3 to 3.5 times, prolonging and shrinking, depending on the alloy type, as shown in the table below.