Veterans in the machine tool industry know that machining centers have a distinction between hard guide rail and linear guide rail. People who do not specialize in manufacturing machining centers often have questions when they encounter these two products. What is the difference between the two? Which one is better and more suitable for you?

Today, I have sorted out some materials for you to take readers to understand the mysteries.

What are?hard guide rail?and linear guide rail?

hard guide rail refers to hard guide rail, and linear guide rail refers to linear guide rail.

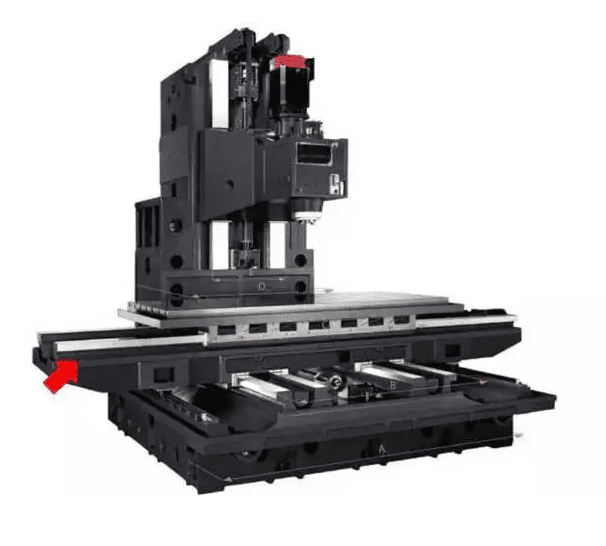

hard guide rail refers to the casting part in which the guide rail and the bed are integrated, and then the guide rail is processed on the basis of the casting. That is, the shape of the guide rail is cast on the bed, and then processed after quenching and grinding. There are also some guide rails that are not necessarily integrated with the bed. For example, the steel inlaid guide rail is nailed to the bed after processing.

The linear guideway usually refers to the rolling guideway, which is used in the linear module often used in the machine tool industry. We usually call this kind of component “l(fā)inear guideway”.

The linear guide rail itself is divided into two parts: slide rail and sliding block.

There are inner circulating balls or rollers in the slider, and the length of the slide rail can be customized. The main difference between the two is that the hard guide rail can bear large cutting force and is mainly used for machine tools over 1.3 meters. Such machine tools are mainly used for mold processing, but the disadvantage is that the guide rail cannot move too fast.

The linear guide rail bears relatively small cutting force, but the guide rail moves very fast. At present, the z-axis moving speed of the drilling rig is generally about 60m. Such a guide rail is mainly used for some relatively small machine tools. In terms of service life, linear guide rail is much higher than hard guide rail.

There is no best but the most suitable hard guide rail and linear guide rail, which have their advantages and disadvantages. Therefore, there is no saying which is better, only the most suitable for enterprise production.

The hard guide rail has large sliding contact surface, good rigidity, strong seismic resistance and load-bearing capacity, which is suitable for heavy-duty cutting. Because of the large contact area of the guide rail, the machine tool runs more smoothly, which is suitable for machine tools with high vibration requirements, such as grinding machines.

The hard guide rail?belongs to dry friction. Due to the large contact surface, the friction resistance is also large, and the moving speed cannot be too fast. At the same time, it is easy to creep, and the gap on the moving surface will lead to machining error.

| linear guide rail | hard guide rail | |

| precision | High | low |

| velocity | Fast | slow |

| property | Good | medium |

| resistance | Small | big |

| carrying capacity | low | high |

| rigidity | Low | high |

| Giá c? | high | low |

| maintenance | Simple | complex |

| repair | simple | complex |

| exchange | Simple | Very complex |

| main axis torque | Below 1950nm | 1000/1450nm |

| application range | Small lathe | Big lathe |

Different applications of hard guide rail and linear guide rail

The maintenance of the machine tool track is the most important. Once the track is not lubricated sufficiently, it will cause the track to burn or wear transition, which is fatal to the accuracy of the machine tool.

Therefore, as a whole, the application of hard guide rail is suitable for heavy cutting, large molds, high hardness workpieces and workpieces with general accuracy requirements.

The rail assembly is simple, and high-quality assembly can be completed with a little training. The cutting force of the rail is smaller than that of the hard guide rail. Now the rail of many large factories has greatly improved its bearing capacity through some structural designs. Of course, it is still relatively small compared with the bearing capacity of the hard guide rail.

The linear guide rail is suitable for high-speed machine and can be cut at high speed. It is suitable for processing products and small precision molds. It has the advantages of fast running speed, high machining precision, low maintenance cost and longer service life than the hard guide rail. The line rail is not perfect either. It is inferior to the hard guide rail in terms of stability and rigidity, and has higher requirements for transportation and processing environment.

To sum up, when selecting a machining center, you should select the products that are suitable for you according to your own needs and conditions, so that the machining effect can reach the ideal state.