Tapping is a challenging machining process because its cutting edge comes into direct contact with the workpiece about 100% of the time. Therefore, various issues such as the workpiece properties, the selection of the tool and the machine tool, and the cutting speed and feed rate, should be considered in advance.

This article will introduce you to the basic knowledge you need to know about taps, including the three common chip flute types of them.

Chip flutes

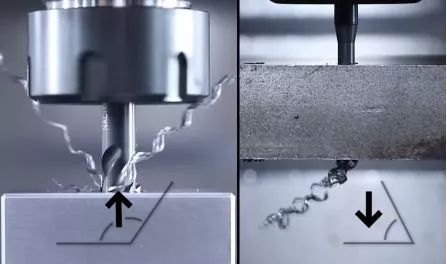

Improper selection of chip flutes of taps can cause difficulty in chip removal, and the cutting chips may wrap around the tool, resulting in machining problems as shown in the figure below.

Common types of tap chip flutes include the following:

- Straight flutes

- Spiral flutes

- Spiral pointed flutes

Please refer to the attached figure for their appearances.

Straight flutes taps

Spiral-fluted taps

Spiral-fluted taps are mainly used for machining blind holes and materials with high hardness and strength.

They are used for machining 400 series stainless steel (with a spiral angle of 15°).

They are used for machining 300 series stainless steel (with a spiral angle of 41°).

Spiral pointed flutes

They are more durable for chip removal than straight flutes and are suitable for through-hole machining. The disadvantage is that the ineffective thread at the tip is too long.

Comparison between Spiral Fluted Taps and Spiral Pointed Taps

Spiral fluted type is suitable for blind holes, and chips are discharged outwards. Spiral pointed taps, on the other hand, discharge chips downwards.

Material selection for taps

Currently, the trend is for cemented carbide taps to gradually replace high-speed steel ones

Nowadays, cemented carbide taps are gradually replacing high-speed steel taps. Like the trend of cemented carbide cutting tools gradually replacing high-speed steel tools in turning, cemented carbide taps are also used more for thread hole machining. Compared with high-speed steel, cemented carbide has high hardness and brittleness, and there is a problem of chip handling when using cemented carbide ones for thread cutting. Despite this, cemented carbide taps perform well in processing cast iron and aluminum alloy materials, and the main form of tool damage is mechanical wear.

Because the automotive industry processes a large number of cast iron and aluminum alloy parts, the use of cemented carbide taps can obtain long tool life. When processing these materials, cemented carbide taps have a longer life than high-speed steel ones. In the automotive industry, the reduction of tap replacement time is a significant factor, and the long life of cemented carbide taps minimizes tap replacement time. Small helix angle cemented carbide taps with surface coatings, such as TiN, TiCN, CrN, or TiAlN, work well when tapping aluminum alloy parts with 8% to 12% silicon content. Taps made of submicron-grain cemented carbide can increase tool toughness without reducing hardness and work well in cutting hardened steel, plastics, and difficult-to-machine nickel-based alloys.

tool coating

After selecting the appropriate material for tap production and pairing it with a special coating surface, such as TiN, TiCN, CrN, or TiAlN, the tap’s life can be significantly increased. These heat-resistant and smooth coatings reduce cutting forces and allow tapping at higher cutting speeds.

Thread cutting equipment for taps

Machine tools

There are two types of processing methods, vertical and horizontal, for thread cutting. For thread cutting, the vertical method is better than the horizontal method. When using the horizontal method, the adequacy of cooling should be considered when the workpiece is cooled externally.

Tap holder

It is recommended to use a dedicated tap holder for thread cutting. For machines with good rigidity and stability, synchronous tap holders should be used as a priority. Conversely, flexible tool holders with axial/radial compensation should be used as much as possible. Except for small diameter taps (<m8), square drive should be used as much as possible.

Cooling conditions

For thread cutting, especially for extrusion tools, the requirement for coolant is lubrication > cooling. The coolant concentration should be greater than 10% when using an emulsion. The actual use of coolant should be adjusted according to the machine tool conditions.

Processing parameters for taps

Speed

The speed is given based on the type of tap, material, workpiece material and hardness, and the quality of the thread cutting equipment. Usually, it is selected according to the parameters given by the tap manufacturer. The speed must be reduced under the following conditions: 1poor rigidity of the machine tool;

2large tap deflection;

3insufficient cooling;

4non-uniform material or hardness in the thread cutting area, such as welding spots;

5long tap or extension rod; horizontal processing with external cooling;

6manual operation, such as bench drill and radial drilling.

Feed rate

For rigid tapping, the feed rate should be 1 pitch/revolution. For flexible tapping, if the compensation variables of the tap holder are sufficient, the feed rate should be (0.95-0.98) pitch/revolution.