The Function of the Helix Angle

The larger the helix angle of an end mill, the longer the contact length between the workpiece and the cutting edge. This can reduce the load borne by the cutting edge per unit length, thereby extending the tool life. However, at the same time, cutting resistance increases, so it is necessary to consider using a tool holder with high clamping rigidity.

Relationship between Helix Angle and Other Elements

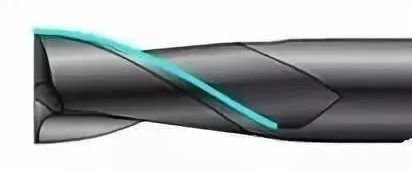

Helix Angle and Cutting Edge Length

For end mills with a small helix angle, the cutting edge is shorter (length indicated by the blue line).

For end mills with a large helix angle, the cutting edge is longer (length indicated by the red line).

Helix Angle and Cutting Resistance

The tangential cutting resistance decreases with the increase of the helix angle, while the axial cutting resistance increases with the increase of the helix angle.

Helix Angle and Lead Angle

The increase in helix angle results in an actual increase in the lead angle of the end mill, making the cutting edge sharper.

Helix Angle and Machined Surface Precision

Generally, the perpendicularity and flatness tolerances of the machined surface increase with the increase of the helix angle. However, after the helix angle exceeds 40°, there is a tendency for these tolerances to decrease with the further increase of the helix angle.

Helix Angle and Tool Life

The wear rate of the circumferential cutting edge is generally proportional to the size of the helix angle. On the other hand, when the helix angle is very small, even slight tool wear significantly reduces the cutting performance, leading to vibration and rendering the tool unusable. When the helix angle is too large, tool rigidity decreases, leading to a reduction in tool life.

Helix Angle and Workpiece Material

When machining soft materials with low hardness, a large helix angle is used to increase the lead angle and improve the sharpness of the cutting edge. When machining hard materials with high hardness, a small helix angle is used to reduce the lead angle and enhance the rigidity of the cutting edge.

Principles for Choosing the Helix Angle

For difficult-to-cut materials such as stainless steel with low thermal conductivity and significant heat impact on the cutting edge, using an end mill with a large helix angle in cutting helps extend the tool life.

Furthermore, the characteristics of the finished surface change due to the helix angle. For instance, when smooth finishing is required, there are times when end mills with a large helix angle can be employed. However, when using end mills with a large helix angle, cutting resistance and the force causing the right helix angle tool to pull outward increase. Therefore, corresponding measures must be taken, such as using a tool holder with high clamping rigidity. Although this ensures the tool’s rigidity, in cases where the workpiece rigidity is low, such as in thin sheet processing, end mills with a small helix angle are sometimes used.

Characteristics of Different Helix Angles

End mill with a large helix angle of 50 degrees

This vertical milling cutter is designed for precision side milling. It offers excellent tool rigidity, minimizing deflection during side milling, and simultaneously suppressing the risk of tool tip chipping to the greatest extent possible.

60° helix angle vertical milling cutter

This helix angle is suitable for high-speed cutting of difficult-to-cut materials such as SUS304 stainless steel. For hard-to-cut materials with low thermal conductivity, where the temperature at the cutting edge is prone to rise during cutting, a 60° helix angle helps suppress the impact of cutting heat on the cutting edge.

45° helix angle vertical milling cutter

Adopting a 45° helix angle can better achieve high-speed machining and high wear resistance.

Tóm l??c

In conclusion, the helix angle is one of the primary parameters of helical-edged end mills, and changes in the helix angle significantly impact the cutting performance of the tool. With the development of CNC machining technology and flexible manufacturing, altering the helix angle in tool manufacturing has become feasible and straightforward. Further in-depth research into the various effects of helix angle size on the cutting performance of helical-edged end mills, when combined with the performance of machine tools and fixtures, and considering factors such as material properties, machining precision, efficiency, tool material, and tool life, can undoubtedly play a crucial role in optimizing the helix angle size and promote efficient and precise milling processes.