PVD and CVD are currently very common treatment for surface treatments on tools and molds. CVD is based on chemical vapor deposition, while PVD is based on physical vapor deposition, due to their differences in principle, resulting in their final coating. Layer results are also different, with different emphasis on applications.

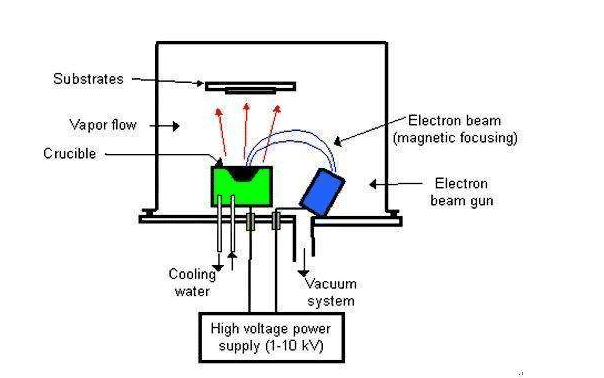

PVD (physical vapor deposition) is a low-voltage and high-current arc discharge technology that evaporates a metal target and ionizes both the vaporized substance and the gas under vacuum conditions. A 10um ultra-hard film is formed on the surface of the product. A cutting-edge technology in the field of new technology surface treatment. This super-hard PVD coated film silverware is formed into a film in a vacuum-tight chamber, so it hardly pollutes the environment. PVD can easily obtain ceramic coatings and composite coatings with high hardness and high wear resistance which are difficult to obtain by other methods. It can be applied to tool mold parts to double the life and achieve low cost and high profit.

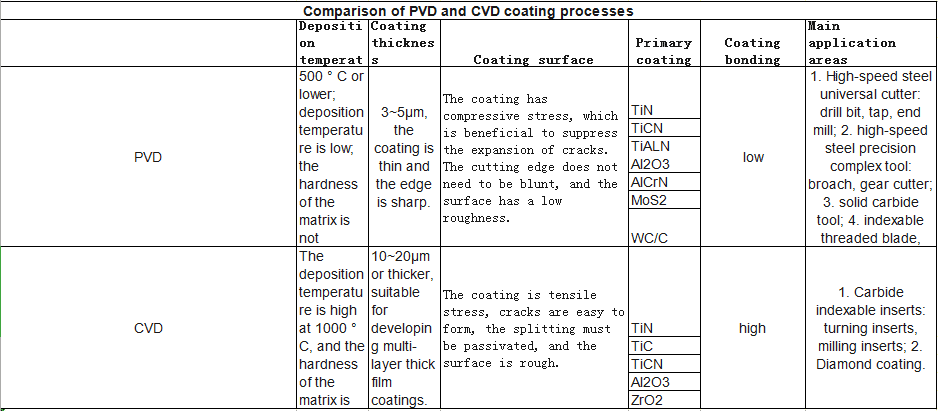

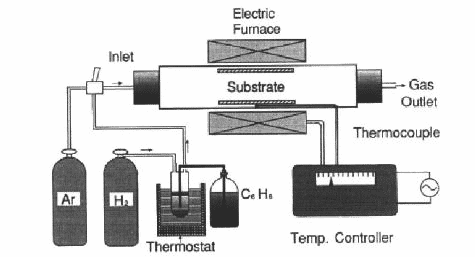

PVD is thinner than CVD, CVD coating thickness is 10~20μm, and PVD coating thickness is only about 3~5μm. The processing temperature of PVD is about 500 °C, while the temperature inside the furnace of CVD is 800~1000 °C. It can be seen that because of the high temperature, CVD has high temperature resistance requirements for the material to be treated. We can hardly see anything other than cemented carbide on CVD-treated tools because only the hard alloys in the mainstream cutting materials can withstand such high temperatures.

In addition, the CVD coating has a relatively high processing temperature due to its thick thickness, and a tensile stress is easily generated on the surface during cooling to form fine cracks. These cracks are easily spread under external impact (for example: milling), and the coating peels off once it extends through the entire coating, thereby depriving the tool base of coating protection. Therefore, CVD coated tools are used in a large number of turning inserts because the cutting force is uniform and continuous during the entire cutting process. At this time, the CVD coating is reflected by the wear resistance of the thickness. It is clear.

In contrast, interrupted cutting represented by milling. During the cutting process, the continuous cutting of the cutting edge impacts the coating and the surface of the tool. The lower processing temperature of PVD (around 500 °C) causes it to form compressive stress rather than tensile stress during cooling, thereby producing the effect of preventing crack formation and expansion. In addition, due to the thin thickness of the PVD coating, the geometry of the blade is not changed much, which can largely preserve the sharpness of the blade and reduce the cutting force and heat of cutting. In summary, it can be seen that PVD is more suitable for intermittent milling and almost all of the overall tools.

To be fair, CVD has an advantage over conventional PVD technology that is difficult to catch up with PVD, the most commonly used CVD coating material, Al2O3. Al2O3 has very good physical and chemical stability, is hard and wear resistant, and is extremely low cost, but it is difficult to achieve on ordinary PVD due to the manufacturing process. Of course, due to the many other advantages of PVD, and because of its continuous expansion in coating materials in recent years, its performance has gradually outperformed CVD in more and more aspects. Its current market share in the world tool market has gradually increased from 20% to 30% more than a decade ago to over 50% now.