Straight Shank Solid Carbide Twist Drills For Aluminium

| Product Name | Solid Carbide Twist Drill Bit | ||

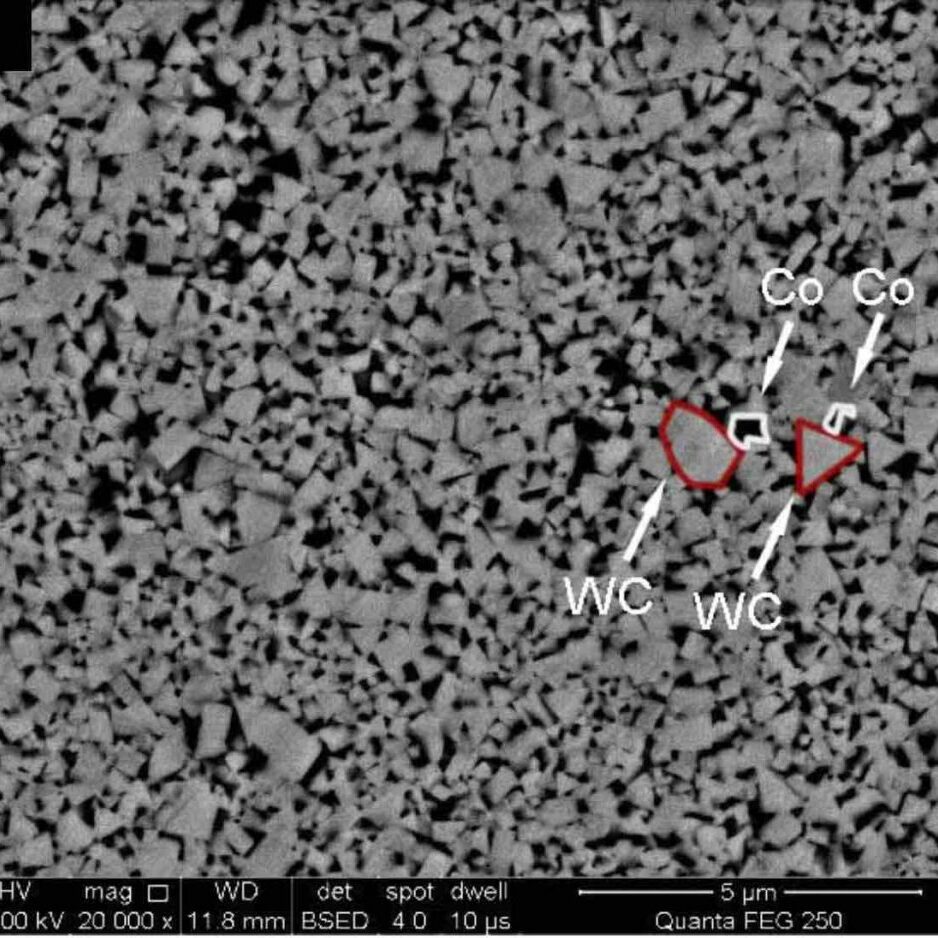

| Material | Tungsten Carbide | ||

| HRC | 45-50° | ||

| Coating | Uncoated | ||

| Top Angle | 118°~140° | ||

| Suitable for | Aluminium, Aluminium Alloy | ||

MAIN FEATURES

Solid Carbide Twist Drills Bits are cutting tools for creating circular holes in the workpiece. We offers a standard selection of solid carbide drills along with customization services.

We use high-quality tungsten carbide rods, high-precision imported Germany Walter CNC machine to manufacture these drills, ensuring?high concentricity and dimensional accuracy.

- Non-Coolant and Coolant Versions

- Various Tool Lengths

- Metric and Inch

- Various Coatings Available

- Standards and OEM

| SPECIFICATIONS: | ||||

| PRODUCT NAME | Cutting? Diameter(D1) |

Cutting? Length(L1) |

Shank? Diameter(D) |

Overall? Length(L) |

| Solid Carbide?Twist Drill 3XD | 3.0-3.7 | 6 | 20 | 62 |

| 3.8-4.7 | 6 | 24 | 66 | |

| 4.8-6.0 | 6 | 24 | 66 | |

| 6.1-7.0 | 8 | 34 | 79 | |

| 7.1-8.0 | 8 | 41 | 79 | |

| 8.1-10.0 | 10 | 47 | 89 | |

| 10.1-12.0 | 12 | 55 | 102 | |

| 12.1-14.0 | 14 | 60 | 107 | |

| 14.1-16.0 | 16 | 65 | 115 | |

| 16.1-18.0 | 18 | 73 | 123 | |

| 18.1-20.0 | 20 | 79 | 131 | |

| Coolant?Solid Carbide?Twist Drill 3XD | 3.0-3.7 | 6 | 20 | 62 |

| 3.8-4.7 | 6 | 24 | 66 | |

| 4.8-6.0 | 6 | 28 | 66 | |

| 6.1-7.0 | 8 | 34 | 79 | |

| 7.1-8.0 | 8 | 41 | 79 | |

| 8.1-10.0 | 10 | 47 | 89 | |

| 10.1-12.0 | 12 | 55 | 102 | |

| 12.1-14.0 | 14 | 60 | 107 | |

| 14.1-16.0 | 16 | 65 | 115 | |

| 16.1-18.0 | 18 | 73 | 123 | |

| 18.1-20.0 | 20 | 79 | 131 | |

| Solid Carbide?Twist Drill 5XD | 3.0-3.7 | 6 | 28 | 66 |

| 3.8-4.7 | 6 | 36 | 74 | |

| 4.8-6.0 | 6 | 44 | 82 | |

| 6.1-8.0 | 8 | 53 | 91 | |

| 8.1-10.0 | 10 | 61 | 103 | |

| 10.1-12.0 | 12 | 71 | 118 | |

| 12.1-14.0 | 14 | 77 | 124 | |

| 14.1-16.0 | 16 | 83 | 133 | |

| 16.1-18.0 | 18 | 93 | 143 | |

| 18.1-20.0 | 20 | 101 | 153 | |

| Coolant?Solid Carbide?Twist Drill 5XD | 3.0-3.7 | 6 | 28 | 66 |

| 3.8-4.7 | 6 | 36 | 74 | |

| 4.8-6.0 | 6 | 44 | 82 | |

| 6.1-8.0 | 8 | 53 | 91 | |

| 8.1-10.0 | 10 | 61 | 103 | |

| 10.1-12.0 | 12 | 71 | 118 | |

| 12.1-14.0 | 14 | 77 | 124 | |

| 14.1-16.0 | 16 | 83 | 133 | |

| 16.1-18.0 | 18 | 93 | 143 | |

| 18.1-20.0 | 20 | 101 | 153 | |

| Coolant?Solid Carbide?Twist Drill 8XD | 3.0-3.7 | 6 | 34 | 72 |

| 3.8-4.7 | 6 | 43 | 81 | |

| 4.8-6.0 | 6 | 57 | 95 | |

| 6.1-8.0 | 8 | 76 | 114 | |

| 8.1-10.0 | 10 | 95 | 142 | |

| 10.1-12.0 | 12 | 114 | 162 | |

| 12.1-14.0 | 14 | 133 | 182 | |

| 14.1-16.0 | 16 | 152 | 203 | |

| 16.1-18.0 | 18 | 171 | 222 | |

| 18.1-20.0 | 20 | 190 | 243 | |

Straight Shank Solid Carbide Twist Drills For Stainless Steels

| Product Name | Solid Carbide Twist Drill Bit | ||

| Material | Tungsten Carbide | ||

| HRC | 50-65° | ||

| Coating | AlcrN/TisiN | ||

| Top Angle | 118°~140° | ||

| Suitable for | Stainless steel, Titanium Alloys,? Heat Resistant Alloy | ||

MAIN FEATURES

Solid Carbide Twist Drills Bits are cutting tools for creating circular holes in the workpiece. We offers a standard selection of solid carbide drills along with customization services.

We use high-quality tungsten carbide rods, high-precision imported Germany Walter CNC machine to manufacture these drills, ensuring?high concentricity and dimensional accuracy.

- Non-Coolant and Coolant Versions

- Various Tool Lengths

- Metric and Inch

- Various Coatings Available

- Standards and OEM

| SPECIFICATIONS: | ||||

| PRODUCT NAME | Cutting? Diameter(D1) |

Cutting? Length(L1) |

Shank? Diameter(D) |

Overall? Length(L) |

| Solid Carbide?Twist Drill 3XD | 3.0-3.7 | 6 | 20 | 62 |

| 3.8-4.7 | 6 | 24 | 66 | |

| 4.8-6.0 | 6 | 24 | 66 | |

| 6.1-7.0 | 8 | 34 | 79 | |

| 7.1-8.0 | 8 | 41 | 79 | |

| 8.1-10.0 | 10 | 47 | 89 | |

| 10.1-12.0 | 12 | 55 | 102 | |

| 12.1-14.0 | 14 | 60 | 107 | |

| 14.1-16.0 | 16 | 65 | 115 | |

| 16.1-18.0 | 18 | 73 | 123 | |

| 18.1-20.0 | 20 | 79 | 131 | |

| Coolant?Solid Carbide?Twist Drill 3XD | 3.0-3.7 | 6 | 20 | 62 |

| 3.8-4.7 | 6 | 24 | 66 | |

| 4.8-6.0 | 6 | 28 | 66 | |

| 6.1-7.0 | 8 | 34 | 79 | |

| 7.1-8.0 | 8 | 41 | 79 | |

| 8.1-10.0 | 10 | 47 | 89 | |

| 10.1-12.0 | 12 | 55 | 102 | |

| 12.1-14.0 | 14 | 60 | 107 | |

| 14.1-16.0 | 16 | 65 | 115 | |

| 16.1-18.0 | 18 | 73 | 123 | |

| 18.1-20.0 | 20 | 79 | 131 | |

| Solid Carbide?Twist Drill 5XD | 3.0-3.7 | 6 | 28 | 66 |

| 3.8-4.7 | 6 | 36 | 74 | |

| 4.8-6.0 | 6 | 44 | 82 | |

| 6.1-8.0 | 8 | 53 | 91 | |

| 8.1-10.0 | 10 | 61 | 103 | |

| 10.1-12.0 | 12 | 71 | 118 | |

| 12.1-14.0 | 14 | 77 | 124 | |

| 14.1-16.0 | 16 | 83 | 133 | |

| 16.1-18.0 | 18 | 93 | 143 | |

| 18.1-20.0 | 20 | 101 | 153 | |

| Coolant?Solid Carbide?Twist Drill 5XD | 3.0-3.7 | 6 | 28 | 66 |

| 3.8-4.7 | 6 | 36 | 74 | |

| 4.8-6.0 | 6 | 44 | 82 | |

| 6.1-8.0 | 8 | 53 | 91 | |

| 8.1-10.0 | 10 | 61 | 103 | |

| 10.1-12.0 | 12 | 71 | 118 | |

| 12.1-14.0 | 14 | 77 | 124 | |

| 14.1-16.0 | 16 | 83 | 133 | |

| 16.1-18.0 | 18 | 93 | 143 | |

| 18.1-20.0 | 20 | 101 | 153 | |

| Coolant?Solid Carbide?Twist Drill 8XD | 3.0-3.7 | 6 | 34 | 72 |

| 3.8-4.7 | 6 | 43 | 81 | |

| 4.8-6.0 | 6 | 57 | 95 | |

| 6.1-8.0 | 8 | 76 | 114 | |

| 8.1-10.0 | 10 | 95 | 142 | |

| 10.1-12.0 | 12 | 114 | 162 | |

| 12.1-14.0 | 14 | 133 | 182 | |

| 14.1-16.0 | 16 | 152 | 203 | |

| 16.1-18.0 | 18 | 171 | 222 | |

| 18.1-20.0 | 20 | 190 | 243 | |

Straight Shank Solid Carbide Twist Drills? For General Purposes

| Product Name | Solid Carbide Twist Drill Bit | ||

| Material | Tungsten Carbide | ||

| HRC | 45-60° | ||

| Coating | Balzers HELICA,FN | ||

| Top Angle | 118°~140° | ||

| Suitable for | Structural steel, alloy steel, stainless steel, cast iron and other common materials? | ||

MAIN FEATURES

Solid Carbide Twist Drills Bits are cutting tools for creating circular holes in the workpiece. We offer a standard selection of solid carbide drills along with customization services.

We use high-quality tungsten carbide rods, high-precision imported Germany Walter CNC machine to manufacture these drills, ensuring?high concentricity and dimensional accuracy.

- Non-Coolant and Coolant Versions

- Various Tool Lengths

- Metric and Inch

- Various Coatings Available

- Standards and OEM

| SPECIFICATIONS: | ||||

| PRODUCT NAME | Cutting? Diameter(D1) |

Cutting? Length(L1) |

Shank? Diameter(D) |

Overall? Length(L) |

| Solid Carbide?Twist Drill 3XD | 3.0-3.7 | 6 | 20 | 62 |

| 3.8-4.7 | 6 | 24 | 66 | |

| 4.8-6.0 | 6 | 24 | 66 | |

| 6.1-7.0 | 8 | 34 | 79 | |

| 7.1-8.0 | 8 | 41 | 79 | |

| 8.1-10.0 | 10 | 47 | 89 | |

| 10.1-12.0 | 12 | 55 | 102 | |

| 12.1-14.0 | 14 | 60 | 107 | |

| 14.1-16.0 | 16 | 65 | 115 | |

| 16.1-18.0 | 18 | 73 | 123 | |

| 18.1-20.0 | 20 | 79 | 131 | |

| Coolant?Solid Carbide?Twist Drill 3XD | 3.0-3.7 | 6 | 20 | 62 |

| 3.8-4.7 | 6 | 24 | 66 | |

| 4.8-6.0 | 6 | 28 | 66 | |

| 6.1-7.0 | 8 | 34 | 79 | |

| 7.1-8.0 | 8 | 41 | 79 | |

| 8.1-10.0 | 10 | 47 | 89 | |

| 10.1-12.0 | 12 | 55 | 102 | |

| 12.1-14.0 | 14 | 60 | 107 | |

| 14.1-16.0 | 16 | 65 | 115 | |

| 16.1-18.0 | 18 | 73 | 123 | |

| 18.1-20.0 | 20 | 79 | 131 | |

| Solid Carbide?Twist Drill 5XD | 3.0-3.7 | 6 | 28 | 66 |

| 3.8-4.7 | 6 | 36 | 74 | |

| 4.8-6.0 | 6 | 44 | 82 | |

| 6.1-8.0 | 8 | 53 | 91 | |

| 8.1-10.0 | 10 | 61 | 103 | |

| 10.1-12.0 | 12 | 71 | 118 | |

| 12.1-14.0 | 14 | 77 | 124 | |

| 14.1-16.0 | 16 | 83 | 133 | |

| 16.1-18.0 | 18 | 93 | 143 | |

| 18.1-20.0 | 20 | 101 | 153 | |

| Coolant?Solid Carbide?Twist Drill 5XD | 3.0-3.7 | 6 | 28 | 66 |

| 3.8-4.7 | 6 | 36 | 74 | |

| 4.8-6.0 | 6 | 44 | 82 | |

| 6.1-8.0 | 8 | 53 | 91 | |

| 8.1-10.0 | 10 | 61 | 103 | |

| 10.1-12.0 | 12 | 71 | 118 | |

| 12.1-14.0 | 14 | 77 | 124 | |

| 14.1-16.0 | 16 | 83 | 133 | |

| 16.1-18.0 | 18 | 93 | 143 | |

| 18.1-20.0 | 20 | 101 | 153 | |

| Coolant?Solid Carbide?Twist Drill 8XD | 3.0-3.7 | 6 | 34 | 72 |

| 3.8-4.7 | 6 | 43 | 81 | |

| 4.8-6.0 | 6 | 57 | 95 | |

| 6.1-8.0 | 8 | 76 | 114 | |

| 8.1-10.0 | 10 | 95 | 142 | |

| 10.1-12.0 | 12 | 114 | 162 | |

| 12.1-14.0 | 14 | 133 | 182 | |

| 14.1-16.0 | 16 | 152 | 203 | |

| 16.1-18.0 | 18 | 171 | 222 | |

| 18.1-20.0 | 20 | 190 | 243 | |