Quando obtemos o desenho da pe?a, primeiro selecionamos a pastilha intercambiável com formato adequado de acordo com os requisitos do desenho. Em geral, o torno é usado principalmente para completar o trabalho de torneamento do círculo externo e do furo interno, corte e canal e torneamento de rosca. A sele??o da pastilha depende das condi??es específicas da tecnologia de processamento. Geralmente, deve-se selecionar a pastilha com maior versatilidade e mais arestas de corte na mesma pastilha. O tamanho maior é selecionado para torneamento em desbaste e o tamanho menor é selecionado para torneamento fino e semifino. De acordo com os requisitos do processo, determinamos o formato da pastilha necessário, o comprimento da aresta de corte, o arco da ponta da ferramenta, a espessura da pastilha, o angulo posterior da pastilha e a precis?o da pastilha.

Selecting the shape of the insert

1.outside turning inserts

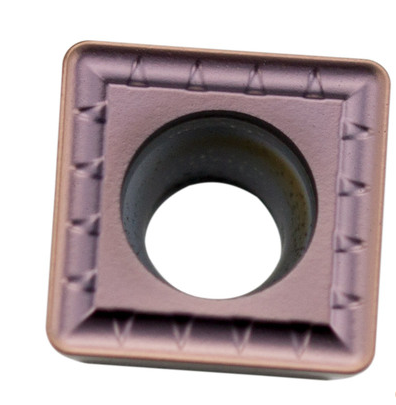

S-shaped: four cutting edges, short cutting edge (refers to the same diameter of inscribed circle), high strength of tool tip, mainly used for 75 ° and 45 ° turning tools, and for processing through holes in internal hole cutters.

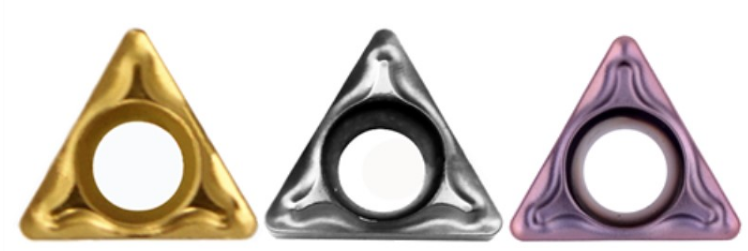

T-shape: three edge, long edge and low strength. The insert?with offset angle is often used to improve the strength of tool tip. It is mainly used for 90 ° turning tools. The inner hole turning tool is mainly used for processing blind hole and step hole.?

C shape: there are two kinds of insert angle. The strength of the two tool tips with 100 ° tool tip angle is high. Generally, it is made into 75 ° turning tool for rough turning of the outer circle and end face. The strength of the two edge edges of the 80 ° insert angle is high. It can be used to process the end face or cylindrical surface without changing the tool. The inner hole turning tool is generally used for processing step holes.

R-shape: round cutting edge, used for machining special circular arc surface, with high insert?utilization rate but large radial force. ?

D-shape: it has two long cutting edges, 55 ° angle and low strength. It is mainly used for profiling. When 93 ° turning tool is made, the cutting angle shall not be greater than 27 ° to 30%; when 62.5 ° turning tool is made, the cutting angle shall not be greater than 57 ° to 60 ° and it can be used for step hole and shallow back cleaning when machining inner hole.

V-shaped: two cutting edges and long, the cutting edge angle is 35 ° and the cutting point strength is low, which is used for profiling. The cutting angle is not more than 50 ° when making 93 ° turning tool, not more than 70 ° when making 72.5 ° turning tool, and no more than 35 ° when making 107.5 ° turning tool.

2. Cutting and grooving inserts:

1.Cutting insert

Generally, the cutting insert which directly presses the chip breaking groove is used on the numerical control lathe. It can make the chip transverse contraction deformation, cutting is light and fast, and chip breaking is reliable. In addition, its side deflection angle and side back angle are very large, cutting heat generation is less, service life is long, but the price is higher.

2. Grooving insert:

generally, the deep groove cutting insert?is used, and the shallow groove cutting insert?is formed insert. For example, vertical grooving insert, flat grooving insert, strip grooving insert?and step clearing arc root groove insert, the groove width accuracy of these inserts?is high.

3. Threaded insert:

L-shaped insert?is commonly used. This insert?can be reground and its price is cheap, but it can’t cut the top of teeth. For the thread with high cutting accuracy, the insert?with good tooth shape should be used. Because of the different tooth shape sizes of the internal and external threads, it is divided into internal and external thread inserts. Its pitch is fixed and can be used to cut out the top of the tooth. As a clamping method, there are two kinds of clamping methods: one is the insert?without hole, which is clamped by upward pressure type, and the other is the insert?with chip breaking groove and clamping hole, which is clamped by pressing hole type plum blossom screw.

Cutting edge length

Cutting edge length: it should be selected according to the back feed. Generally, the cutting edge length of slotted insert should be no less than 1.5 times of the back feed, and the cutting edge length of the closed groove insert should be no less than 2 times of the back feed.

Tool Nose Arc

Tool tip arc: when rough turning, as long as the rigidity is allowed, it can be touched as much as possible. Generally, the radius of tool tip arc is smaller when the rigidity is allowed. However, when the rigidity is allowed, it should be selected from a larger value. The commonly used circle radii for pressing are 0.4, 0.8, 1.2, 2.4, etc.

insert?thickness

insert thickness: the selection principle is to make the insert have enough strength to bear the cutting force, which is usually selected according to the back feed and feed rate. For example, some ceramic inserts need to use thicker inserts.

insert?back angle

insert back angle: commonly used are:

0 ° code n

5 ° code B

7 ° code C

11 ° code P.

0 ° back angle is generally used for rough and semi finish turning, 5 ° for rough turning, 7 ° for 7 ° for 11 ° for semi finishing, finishing turning, profiling and inner hole machining.

insert?accuracy

insert accuracy: there are 16 kinds of indexable inserts specified by the state, among which 6 kinds are suitable for turning tools, with the codes of H, e, G, m, N, u, with H being the highest and u being the lowest. The rough and semi finishing machining of ordinary lathes is of class u, and those with higher requirements for the position of tool tip or CNC lathes use M, and the more advanced ones use G.

After the above steps, we have basically determined what kind of insert?should be used. In the next step, we need to further check the electronic samples of the insert?manufacturer, and finally determine the type of insert?to be used according to the materials and precision to be processed.