This article systematically introduces the principles of tool selection in turning operations, focusing on the selection methods for external turning inserts.Through practical examples of different turning types, it helps readers master key application techniques.

Basic Principles of Tool Selection

When selecting tools, clamping reliability and modular tool priority must be considered.During the turning process, ensuring secure clamping between the insert and tool holder is critical as it directly affects machining stability.

The type of tool holder selected is influenced by the lead angle (entering angle), shape, and size of the insert being used.Meanwhile, corresponding tool holder systems should be chosen based on different operation types.Additionally, deciding between negative or positive rake angle inserts is an important consideration.To facilitate replacement and adjustment, modular tool options should be prioritized.

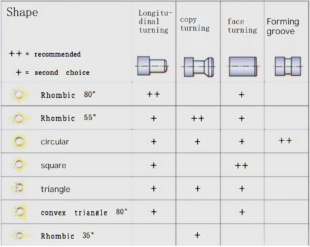

Next, we will delve into the selection methods for external turning inserts. One of the four main application areas is longitudinal turning or face turning, which represents the most common type of turning operation.

Different Turning Types

Longitudinal Turning

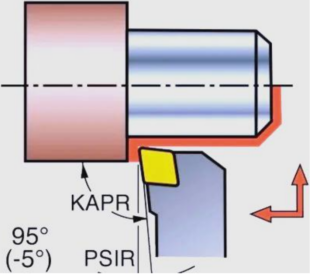

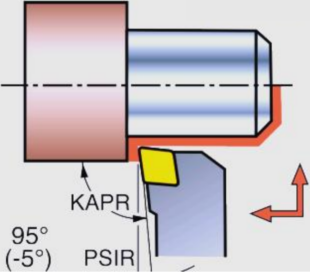

In longitudinal turning or face turning, diamond-shaped C-type inserts paired with appropriate lead angles constitute the most commonly implemented solution.

In longitudinal turning or face turning, the diamond-shaped C-type (80°) insert is a commonly used option.

The tool holder’s lead angle is typically set at 95° and 93° (entering angles of -5° and -3°) to ensure optimal cutting performance.

In addition to C-type inserts, D-type (55°), W-type (80°), and T-type (60°) inserts can serve as alternatives to accommodate different requirements.

Contour Turning

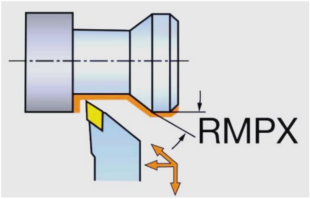

Selecting appropriate lead angles to ensure machining versatility and accessibility is crucial in contour turning.

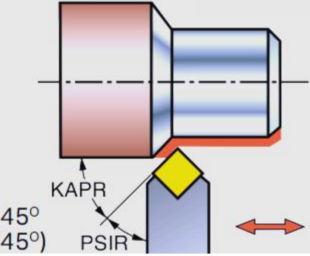

In contour turning processes, selecting an appropriate KAPR (entering angle) is crucial.

Typically, a 93° lead angle (corresponding to a -3° entering angle) is most commonly used as it achieves an internal contour angle of 22°-27°, ensuring machining versatility and accessibility.

D-type (55°) and V-type (35°) inserts serve as frequently used alternative options to meet different cutting requirements.

Face Turning

Tools require radial feed movement with proper lead angle selection to ensure cutting stability and machining quality.

In face turning, tools feed radially to complete workpiece machining.

This turning method demands appropriate insert and lead angle selection to guarantee process stability and output quality.

Common lead angles include 75° and 95°/91°, with corresponding entering angles of 15° and -5°/-1° respectively, fulfilling diverse cutting needs.

Additionally, C-type (80°) and S-type (90°) inserts are standard alternative choices.

Contour Groove Turning

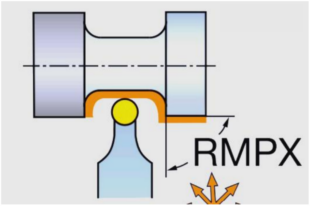

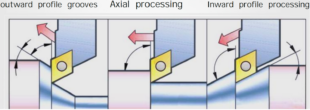

Implementing round inserts for shallow grooving to enhance production efficiency represents a key methodology in contour groove turning.

An effective method for shallow grooving or groove widening operations.

Round Insert Performance

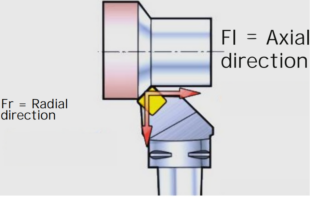

Round inserts demonstrate excellent performance in plunge turning, suitable for both radial and axial feed directions, significantly enhancing machining flexibility.

The 90° neutral holder design represents the most common round insert configuration, particularly favored in face turning applications.

Lead Angle & Contour Angle Effects

Large Lead Angle Advantages

Effectively directs cutting forces

Ideal for shoulder turning operations

Note: Potential machining quality impacts constitute a distinctive characteristic of large lead angle designs.

In face turning operations, the large lead angle (or small entering angle) design effectively directs cutting forces toward the chuck, enhancing machining stability.

This configuration is suitable for shoulder turning, expanding processing capabilities.

However, when machining superalloys and hard materials, groove wear may potentially affect machining quality.

Advantages of Small Lead Angle

Concentrated cutting forces adapt well to multiple working conditions

Note: The core advantage of small lead angle design lies in mitigating groove wear concerns

The small lead angle design (i.e., large entering angle) offers the following benefits in practical applications:

Concentrated cutting forces facilitate stable chuck control

Thinner chip thickness during machining helps improve productivity

Reduced groove wear extends tool life

Contour Angle Selection

Proper selection ensures machining strength and tool longevity. The influence on cutting force distribution is a key factor in contour angle selection.

During contour turning, cutting conditions vary with changes in cutting depth, chip thickness, and cutting speed.

To ensure both strength and cost-effectiveness in the cutting process, we must select the maximum tool nose angle suitable for the insert.

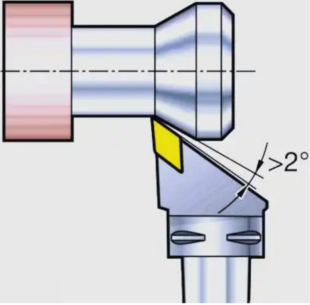

When choosing an appropriate contour angle, detailed analysis of the workpiece profile is essential to maintain proper clearance between the material and cutting edge.

At the same time, to ensure the safety and efficiency of the cutting process, a clearance angle of at least 2° should be maintained between the workpiece and the blade.

Cutting Force Influence

The cutting force needs to be balanced. A larger lead angle can reduce axial cutting force, thereby improving the stability of the cutting process.

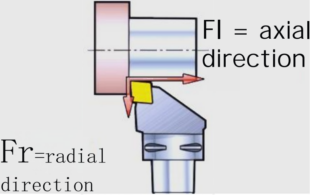

During the copying turning process, axial and radial cutting forces are important factors to consider. It is necessary to monitor the variations in these cutting forces.

Adopting a strategy with a large lead angle (i.e., a small entering angle) can effectively reduce axial cutting force, thereby improving the stability and safety of the cutting process.

However, when using a small lead angle (i.e., a large entering angle), it was observed that the cutting force was distributed in both axial and radial directions, reducing the tendency for vibration.

Conclus?o

Through systematic analysis in this study, the following key conclusions can be drawn: First, tool selection must comprehensively consider factors such as workpiece material, operation type, and cutting parameters. Second, proper selection of lead angle and profile angle is crucial for machining quality. Finally, understanding the distribution patterns of cutting forces helps optimize the machining process. In practical applications, engineers are advised to flexibly apply the tool selection principles and techniques introduced in this study based on specific working conditions to achieve efficient and precise turning operations. With the continuous advancement of machining technology, ongoing learning and mastery of the latest tool application knowledge will be key to maintaining a competitive edge.