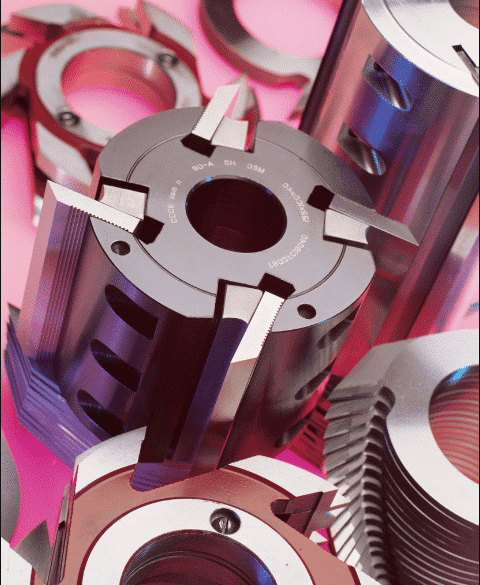

The application of machine tool clamping system is conducive to ensuring the accuracy of workpiece processing and stabilizing product quality, improving labor productivity and reducing costs, improving workers’working conditions and ensuring product safety, expanding the scope of machine tool technology, and realizing “one machine, multi-purpose”.

Characteristics of NC Machiningclamping system

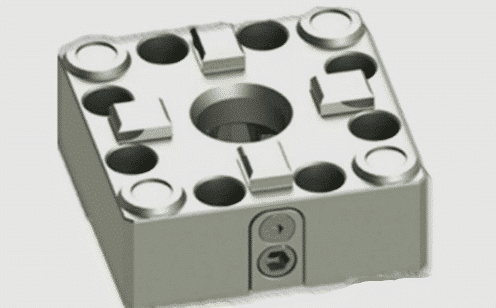

As the clamping system of machine tool, it is necessary to satisfy the clamping requirement of the workpiece in mechanical processing. At the same time, the clamping system of NC machining has its own characteristics. These characteristics are:

1.NC machining is suitable for multi-variety, small and medium-sized batch production. In order to clamp multi-variety workpieces of different sizes and shapes, the clamping system for NC processing should be flexible, and the workpieces of various shapes and sizes can be clamped through appropriate adjustment.

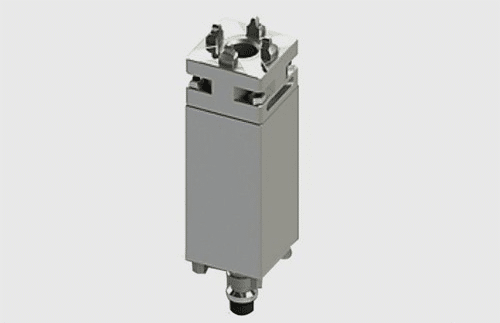

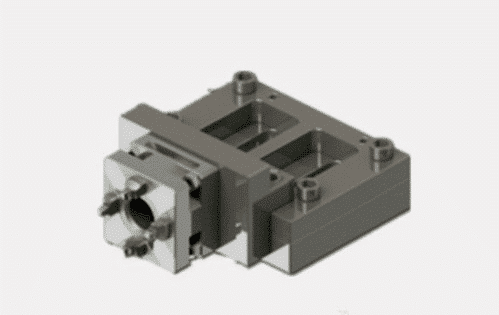

2. The traditional special clamping system has four functions: positioning, clamping, guiding and toolset. The NC machine tools are usually equipped with a contact test probe, tool setter and tool setting parts, which can solve the problem of tool setting by machine tools. Accurate positioning accuracy controlled by the program on the NC machine tool can realize tool guiding function clamping system. Therefore, the clamping system in NC machining generally does not need the function of orientation and toolset. It only needs the function of positioning and clamping to meet the requirements of use, which can simplify the structure of the clamping system.

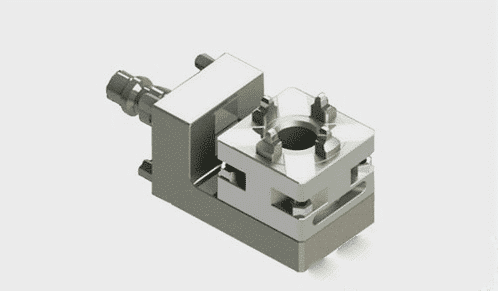

3. In order to adapt to the high efficiency of NC machining, the automatic clamping devices such as pneumatic, hydraulic and electric clamping devices should be used as fast as possible to shorten the auxiliary time.

4. The clamping system itself should have enough rigidity to adapt to large cutting parameters. NC machining has the characteristics of a centralized process. In one clamp of a workpiece, not only rough machining with great cutting force but also finish machining to meet the requirements of the final accuracy of the workpiece, so the rigidity and clamping force of the clamp must meet the requirements of large cutting force.

5. In order to adapt to NC multi-faceted processing, it is necessary to avoid the interference of the clamping system structure, including the components on the clamping system, on the tool trajectory. The clamping system structure should not hinder the multi-faceted processing of various parts of the workpiece by the tool.

6.clamping system positioning should be reliable, positioning elements should have high positioning accuracy, positioning position should be easy to clear debris, no chip retention. If the positioning surface of the workpiece is too small, additional process convex or auxiliary datum can be considered.

7. For the workpiece with small stiffness, the minimum clamping deformation should be guaranteed, such as making the clamping point close to the supporting point, avoiding the clamping force acting on the hollow area of the workpiece, etc. When roughing and finishing are completed in the same process, if the above measures can not control the deformation of the workpiece within the range required by the processing accuracy, the program should be suspended before finishing, so that the operator can change the clamping force (appropriately reduced) before finishing after roughing, so as to reduce the impact of clamping deformation on the processing accuracy.