Características bem conhecidas e aplica??o da fresagem de roscas

Thread milling features and applications:

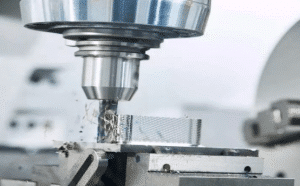

Com a popularidade das máquinas-ferramentas CNC, a tecnologia de fresamento de roscas é cada vez mais utilizada na fabrica??o de máquinas. O fresamento de roscas é uma liga??o de três eixos de uma máquina-ferramenta CNC. A fresa de rosca é usada para fresamento de interpola??o helicoidal para formar uma rosca. A ferramenta se move em um movimento circular em cada plano horizontal e move um passo em um plano vertical. O fresamento de roscas tem muitas vantagens, como alta eficiência de usinagem, alta qualidade de rosca, boa versatilidade de ferramentas e boa seguran?a de processo. Existem muitos tipos de ferramentas de fresamento de roscas usadas atualmente. Este artigo analisa sete fresas comuns para rosqueamento a partir de características de aplica??o, estrutura da ferramenta e tecnologia de usinagem.

1.ordinary machine clamp thread milling cutter

Machine-clamp thread milling cutters are the most common and inexpensive tool in thread milling. They are similar in construction to conventional machine-clamping cutters and consist of reusable toolholders and easily replaceable blades. If you need to machine the taper thread, you can also use the special arbor and blade for machining the taper thread. This blade has a plurality of thread cutting teeth. The tool can process a plurality of thread teeth once a week along the spiral line. A milling cutter with five 2mm thread cutting teeth can machine five thread threads with a thread depth of 10 mm by machining one cycle along the helix. In order to further improve the processing efficiency, a multi-blade machine-type thread milling cutter can be selected.

By increasing the number of cutting edges, the feed rate can be significantly increased, but the radial and axial positioning errors between each of the blades distributed over the circumference can affect the accuracy of the threading. If the thread precision of the multi-blade machine thread milling cutter is not satisfied, you can also try to install only one blade for processing. When selecting a machine-type thread milling cutter, the diameter of the cutter bar and the appropriate blade material should be selected as much as possible according to the diameter, depth and workpiece material of the thread to be machined. The threading depth of the machine-type thread milling cutter is determined by the effective cutting depth of the toolholder. Since the length of the blade is less than the effective depth of cut of the shank, layering is required when the depth of the machined thread is greater than the length of the blade.

2.the ordinary integral thread milling cutter

Integral thread milling cutters are mostly made of solid carbide materials, and some are also coated. The integral thread milling cutter is compact and suitable for machining medium and small diameter threads. It also has an integral thread milling cutter for machining taper threads. These tools have good rigidity, especially the integral thread milling cutter with spiral groove, which can effectively reduce the cutting load and improve the processing efficiency when processing high hardness materials. The cutting edge of the integral thread milling cutter is covered with threaded teeth, and the whole thread processing can be completed by machining one thread along the spiral line. It does not need to be layered like a machine tool, so the processing efficiency is high, but the price is relatively expensive.

3.Overall thread milling cutter with chamfering function

The overall thread milling cutter with chamfering structure is similar to a conventional integral thread milling cutter, but with a special chamfering edge at the root of the cutting edge, the thread end chamfer can be machined while machining the thread. There are three ways to machine the chamfer. When the tool diameter is large enough, the chamfering blade can be used directly to chamfer the chamfer. This method is limited to machining the internal threaded hole chamfer. When the tool diameter is small, the chamfering blade can be used to machine the chamfer by circular motion. However, when chamfering is performed using the chamfering edge of the cutting edge, it should be noted that there should be a certain gap between the cutting portion of the cutter thread and the thread to avoid interference. If the thread depth of the machining is less than the effective cutting length of the tool, the tool will not be able to achieve the chamfering function, so the tool should be selected to match the effective cutting length and the thread depth.

4.thread drilling and milling cutter

The thread drilling and milling cutter is made of solid carbide and is a high-efficiency machining tool for medium and small diameter internal threads. The thread drilling cutter can complete the drilling of the bottom hole, the hole chamfering and the internal thread machining at one time, reducing the number of tools used. However, the disadvantage of this type of tool is its poor versatility and its high price. The tool consists of a drilled portion of the head, a threaded portion in the middle, and a chamfered blade at the root of the cutting edge. The diameter of the drilled part is the bottom diameter of the thread that the tool can machine. Due to the limitation of the diameter of the drilled part, a thread drilling and milling cutter can only process one thread of internal thread. When selecting a thread drilling and milling cutter, not only the threaded hole size to be machined, but also the effective machining length of the tool and the depth of the machined hole should be considered. Otherwise, the chamfering function cannot be realized.

5.thread auger milling cutter

Threaded auger milling cutters are also solid carbide tools for efficient internal threading. They can also be used to machine bottom holes and threads at one time. The tool end has a cutting edge like an end mill. Since the spiral angle of the thread is not large, when the tool makes the helical motion machining thread, the end cutting edge first cuts the workpiece material to machine the bottom hole, and then the thread is machined from the back of the tool. Some threaded auger milling cutters also have chamfered edges that allow for the chamfering of the holes at the same time. The tool has high processing efficiency and is more versatile than the thread drilling and milling cutter. The internal thread diameter of the tool can be processed from d to 2d (d is the diameter of the cutter body).

6.milling deep thread cutter

The milled deep thread cutter is a single tooth thread milling cutter. A general thread milling cutter has a plurality

of threaded teeth on the cutting edge, the tool has a large contact area with the workpiece, and the cutting force is also large, and the diameter of the tool must be smaller than the threaded aperture when machining the internal thread. Due to the limitation of the diameter of the cutter body, the rigidity of the tool is affected, and the tool is unilaterally stressed when milling the thread. When the deep thread is milled, the knife phenomenon is easy to occur and the thread machining accuracy is affected. Therefore, the effective cutting depth of the general thread milling cutter is about 2 times the diameter of the body. The use of single-toothed deep-threaded tools can better overcome the above shortcomings. Due to the reduced cutting force, the thread machining depth can be greatly increased, and the effective cutting depth of the tool can reach 3 to 4 times the diameter of the cutter body.

7.thread milling tool system

Generality and high efficiency are a prominent contradiction of thread milling cutters. Some tools with composite functions have high processing efficiency but poor versatility, while versatile tool efficiency is often not high. To solve this problem, many tool manufacturers have developed modular thread milling tool systems. The tool is generally composed of a shank, a boring chamfering edge, and a universal thread milling cutter. Different types of boring chamfering edges and thread milling cutters can be selected according to the processing requirements. This tool system has good versatility and high processing efficiency, but the tool cost is high.

The above outlines the functions and features of several common thread milling tools. Cooling is also important when milling threads, and it is

recommended to use machines and tools with internal cooling. When the tool rotates at a high speed, the external coolant is not easily introduced by the centrifugal force. In addition to the excellent cooling of the tool, the internal cooling method is more important when the blind hole thread is used to facilitate chip removal. When machining the small diameter internally threaded hole, a higher internal cooling pressure is required. Ensure that the chip removal is smooth. In addition, when selecting thread milling tools, we should also consider the specific processing requirements, such as?production batch, number of screw holes, workpiece material, thread precision, size specifications, and other factors, and comprehensive selection of tools.