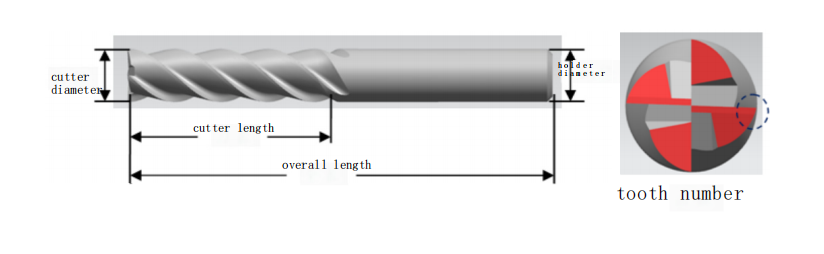

First, let’s take a look at?the components of an end mill, as shown in the diagram below:?

?

The geometric angles to consider when selecting an end mill:

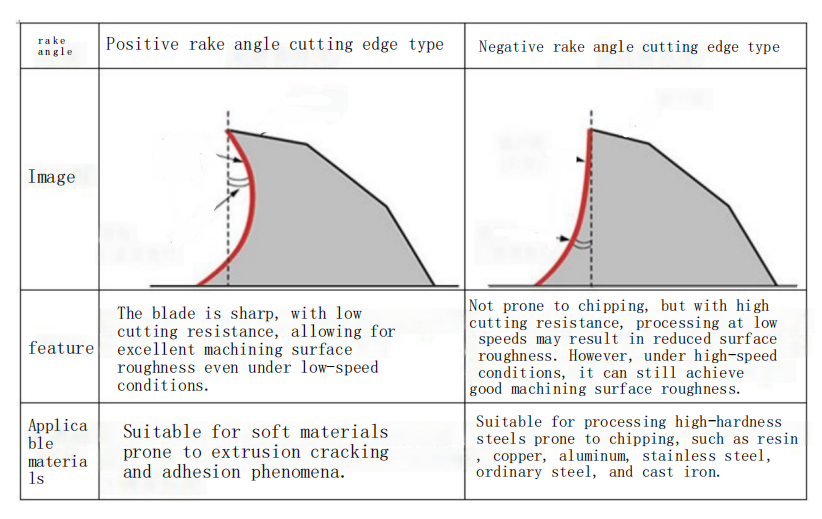

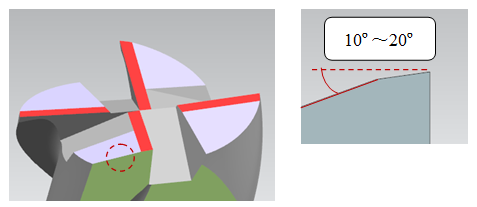

(1)Lead angle (with positive and negative lead angle options, as shown in the diagram)

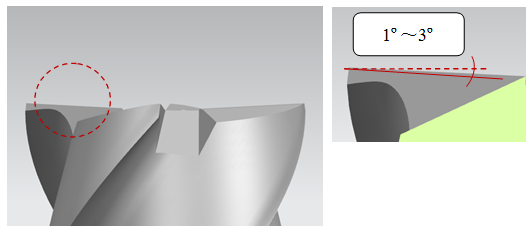

(2)back angle

Function: Primarily reduces friction between the back face and the workpiece.

Applicable area of back angle of end mill

When rough milling or processing workpieces with high strength and hardness, a smaller back angle should be selected to ensure sufficient strength of the cutting edge. When machining workpieces with high plasticity or elasticity, a larger back angle should be chosen to prevent excessive friction contact between the back face and the workpiece due to the elastic recovery of the machined surface.

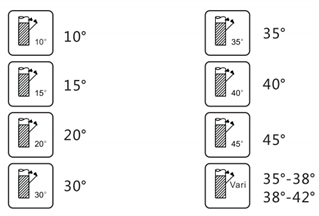

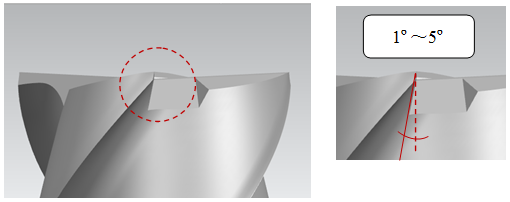

(3)Spiral angle (it is essentially the helix angle of an end mill or a face mill, as shown in the diagram)

Characteristics of the helix angle of an end mill:

A smaller helix angle results in a larger cutting torque and less axial pulling force.

A larger helix angle leads to a greater cutting torque and more axial pulling force.

Comparison between a 30-degree and a 45-degree helix angle for an end mill:

A 30-degree helix angle offers better chip evacuation performance and better rigidity, but it has a larger lead angle, resulting in less sharp cutting edges. It generates more resistance and is suitable for low-speed, high-feed machining.

A 45-degree helix angle provides sharp cutting edges but has inferior chip evacuation performance and lower rigidity. However, with the same number of cutting edges, it offers more space for chip removal. The cutting edges are sharper, making it suitable for high-speed, low-feed machining.

For cutting materials like high-temperature alloys and stainless steel that tend to be sticky, a 45-degree helix angle is more appropriate. On the other hand, a 30-degree helix angle is better suited for cutting materials like steel and cast iron.

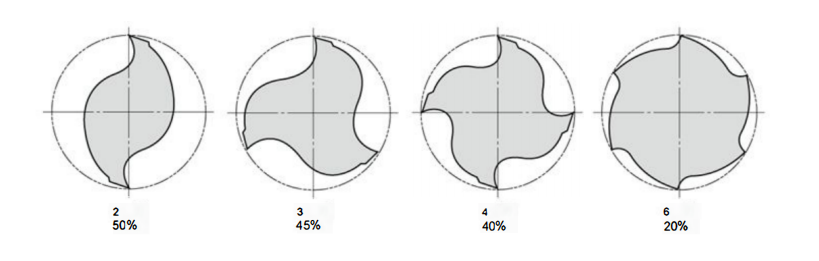

2.Tooth number

It can be seen from the above diagram:

The more cutting edges, the less smooth the chip evacuation, but the tool rigidity is stronger, resulting in better surface roughness.

The fewer cutting edges, the smoother the chip evacuation, but the tool rigidity decreases, leading to poorer surface roughness.

Applications for end mills with different numbers of cutting edges:

Two edges: Suitable for machining keyways.

Three edges: Suitable for machining aluminum, plastic, and electrical wood.

Four edges: Versatile, mainly used for machining steel. For factories that frequently process different materials, a four-edge end mill is ideal to reduce tool costs. For factories with a relatively uniform material, choosing the appropriate number of cutting edges is beneficial for improving cutting efficiency and machining quality.

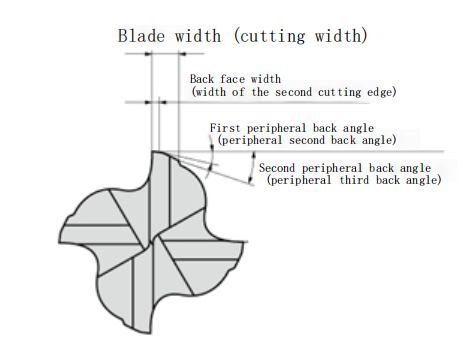

3.The geometric angles to be mastered during the sharpening of an fresa

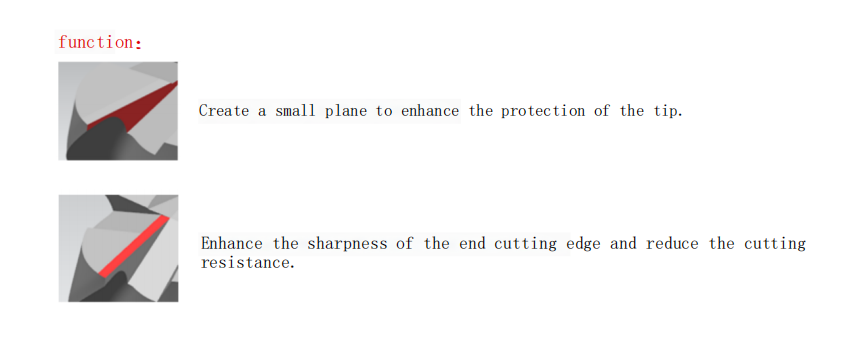

(1)First end face back angle

Function: To prevent friction between the end face and the workpiece bottom surface, enhancing the sharpness of the end face cutting edge.

(2)Second end face back angle

Function: Facilitates the evacuation of chips and debris.

(3)End face concave angle

Function: Prevents the end mill end face from colliding with the workpiece bottom surface and facilitates chip evacuation.

(4)Axial relief angle

The above information provides an overview of several important parameters to consider when selecting end mills. We hope this can be helpful for you.