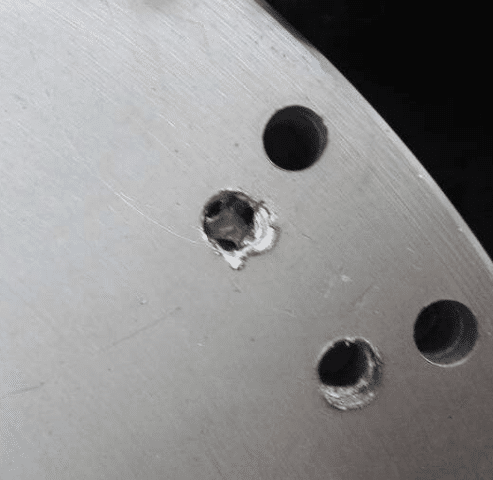

Poor quality tap

Materiais principais, design de ferramentas CNC, tratamento térmico, precis?o de usinagem, qualidade de revestimento e assim por diante. Por exemplo, a diferen?a de tamanho da transi??o da se??o de toque é muito grande ou o filete de transi??o n?o foi projetado, o que leva à concentra??o de tens?o, que é fácil de fraturar na concentra??o de tens?o. A distancia entre a parte de transi??o da se??o transversal na jun??o da al?a e a borda está muito próxima da junta de solda, o que resulta na superposi??o da tens?o de soldagem complexa e na concentra??o de tens?o da transi??o da se??o transversal, resultando em grande concentra??o de tens?o, o que leva à fratura do macho em uso. Por exemplo, processo de tratamento térmico impróprio. Durante o tratamento térmico de machos, podem ocorrer rachaduras se os machos n?o forem pré-aquecidos antes da têmpera, superaquecidos ou superaquecidos após a têmpera, n?o temperados a tempo e limpos muito cedo. Em grande medida, esta é também uma raz?o importante pela qual o desempenho geral das torneiras nacionais é inferior ao das torneiras importadas.

Improper tap selection

High quality taps, such as cobalt containing high speed wire taps, cemented carbide taps and coated taps, should be selected for the parts with too high hardness. In addition, different tap designs are used in different work situations. For example, the number, size and angle of the chip removal slot of the tap have an impact on the chip removal performance.

The tap does not match the processed material

In recent years, more and more attention has been paid to this problem. In the past, domestic manufacturers always thought that imported goods were good and expensive ones were suitable. With the increasing of new materials and the difficulty of machining, in order to meet this need, the variety of tool materials is also increasing. This requires that before tapping, select the right tap products.

The bottom hole diameter is too small

For example, when machining the M5 × 0.5 thread of ferrous metal material, the drill bit with 4.5mm diameter should be used to drill the bottom hole. If the 4.2mm drill bit is used to drill the bottom hole, the cutting part of the tap must be increased during tapping, and the tap will be broken. It is suggested to select the correct bottom hole diameter according to the types of taps and the different materials of the taps. If there is no suitable drill bit, the larger one can be selected.

Material problem of tapping parts

The material of the tapping part is not pure, and there are some hard spots or pores in some parts, which causes the tap to lose balance and break instantly.

The machine does not meet the accuracy requirements of taps

Machine tool and clamping body are also very important, especially for high-quality taps, as long as a certain precision of the machine tool and clamping body can play the tap performance. It is common that the concentricity is not enough. At the beginning of tapping, the starting and positioning of the tap is not correct, that is, the spindle axis is not concentric with the center line of the bottom hole, and the torque is too large in the tapping process, which is the main reason for the tap breaking.

The quality of cutting fluid and lubricating oil is poor

Many domestic enterprises have begun to pay attention to this point. Many companies that have purchased foreign cutting tools and machine tools have a very profound experience. The quality of cutting fluid and lubricating oil has problems. The quality of processed products is easy to appear burr and other adverse conditions, and the service life will be greatly reduced.

Unreasonable cutting speed and feed rate

When machining problems occur, most of the domestic users reduce the cutting speed and feed rate, so that the driving force of the tap is reduced, and the thread accuracy is greatly reduced, which increases the surface roughness of the thread, and the thread diameter and thread accuracy can not be controlled. Of course, burr and other problems are inevitable. However, if the feeding speed is too fast, the torque caused by it is too large, and it is easy to break the tap. The cutting speed of machine tapping is generally 6-15m / min for steel, 5-10m / min for Quenched and tempered steel or hard steel, 2-7m / min for stainless steel and 8-10m / min for cast iron. In the same material, the smaller the tap diameter is, the higher the tap diameter is, the lower the larger tap diameter is.

9. The operator’s technology and skills did not meet the requirements

The above problems need operators to make judgment or feedback to technical personnel, but at present, most operators in China do not pay enough attention to them. For example, when processing blind hole thread, when the tap is about to contact the bottom of the hole, the operator does not realize that the tap is still feeding at the tapping speed when the hole bottom is not reached, or the tap is broken due to forced feeding when chip removal is not smooth. It is suggested that operators should strengthen their sense of responsibility.

It can be seen from the above that the causes of tap fracture can be said to be various. Machine tools, fixtures, workpieces, processes, chucks and cutting tools are all possible, and the real reason may never be found only by talking on paper. As a qualified and responsible tool application engineer, the most important thing is to go deep into the scene, not just by imagination.