Physical Nature of Coating Thickness and Functional Realization

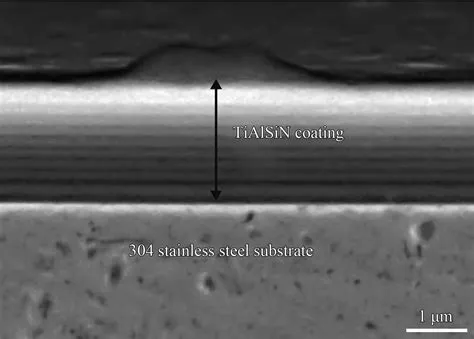

The physical essence of coating technology lies in modifying interfacial properties of the substrate via surface engineering. For rotating tools like drills, coatings must simultaneously reduce friction, enhance surface hardness, and inhibit thermal conduction. When coating thickness ranges from nanometers to micrometers, significant size effects emerge in mechanical properties. Experimental data shows that TiN coatings reach peak microhardness (≈2300HV) at 2-3μm thickness; further increases reduce hardness due to accumulated residual stress. This stress heterogeneity creates preferential paths for microcrack propagation during drilling, especially under interrupted cutting conditions, where excessively thick coatings are prone to delamination.

Thermal barrier effects are vital, but thermal conductivity does not scale linearly with thickness. Finite element simulations reveal that beyond 5μm, AlCrN coatings show diminishing thermal resistance gains. Excessive thickness may impede heat dissipation, intensifying thermal stress concentration in high-speed machining.

Dynamic Evolution of Cutting Edge Geometry

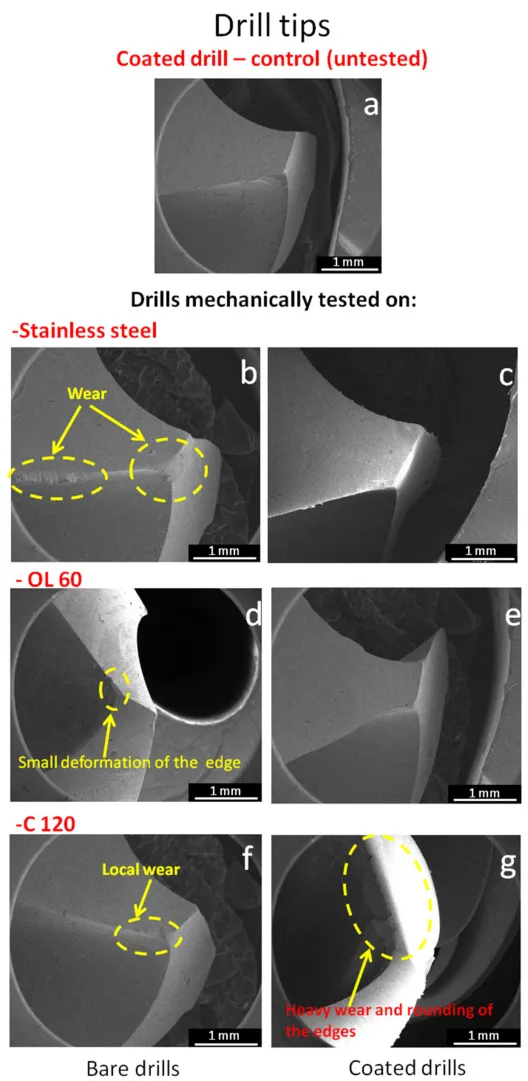

Drill edge sharpness directly affects chip evacuation and force distribution. The “rounding effect” during deposition causes exponential growth in edge radius with thickness. For DLC coatings increasing from 1μm to 3μm, edge radius swells from 3.2μm to 8.7μm, raising cutting resistance by 23%. This geometric dulling is pronounced in ductile materials—aluminum alloy tests show a 15% rise in chip buildup probability per micrometer increase in edge radius. Paradoxically, moderate dulling suppresses edge chipping in brittle materials, highlighting the need for material-specific thickness optimization.

Coating thickness impacts flute hydrodynamics, often overlooked. 3D flow simulations show that when coating exceeds 12% of flute depth, secondary chip flow intensifies, causing blockages. In deep-hole drilling, this exacerbates radial vibration, increasing borehole deviation. A German toolmaker reduced straightness errors by 40% by decreasing TiAlSiN thickness from 4μm to 2.5μm.

Multiscale Correlation of Interface Failure Mechanisms

Coating-substrate bond strength does not monotonically change with thickness. Interface energy tests reveal a 30% strength drop when CrN exceeds ~4μm, due to lattice mismatch stress accumulation. This weakening is perilous under cyclic loading, with failures originating at nanoscale voids. Gradient transition layers enhance critical thickness—inserting a 50nm Ti interlayer between WC-Co and TiCN boosts critical thickness from 3.2μm to 5.1μm.

Cyclic loading reveals time-dependent failure. Accelerated life tests show 3μm AlTiN coatings reduce crack growth by 67% after 10? impacts, benefiting from crack closure effects. Beyond 2×10? cycles, thicker coatings exhibit larger spalling areas, indicating an optimal thickness for fatigue life. This non-monotonic relationship demands precise service life predictions.

Implicit Links to Machining Precision and Surface Integrity

Coating thickness has dual impacts on precision. In micro-hole drilling, a 2μm thickness deviation causes 0.8-1.2% diameter variation. A Japanese firm’s adaptive coating technology deposits 1.5μm at the tip and 2.2μm at margins, controlling diameter?floating?to 0.3%. Such differential designs surpass conventional uniform coatings.

Residual stress in workpieces couples with coating thickness. XRD analysis shows a drop from -450MPa to -280MPa when thickness increases from 1μm to 3μm, potentially reducing dimensional stability. However, thicker coatings reduce heat-affected zones by 35%, critical for aerospace aluminum.

Economic Considerations and Technological Trends

Coating cost scales with thickness squared, but lifespan gains have inflection points. An automotive plant found that increasing TiAlN from 2μm to 3μm raised costs by 18% while only improving life by 12%, resulting in negative ROI. However, nano-multilayered 2.5μm coatings outperformed 3μm by 25%, indicating that thickness alone is suboptimal.

Future coatings will feature intelligent thickness control. Digital twin-based optimization systems are operational, adjusting parameters via real-time force/temperature feedback. A German AI system predicts optimal thickness in 48 hours, enhancing performance by >30%. Dynamic adaptation may revolutionize traditional thickness determination.

Wniosek

Coating thickness orchestrates a precision symphony in drill performance, where each parameter adjustment triggers cascading effects. Modern engineers must transcend empirical selection, establishing multi-physics digital design paradigms. Future breakthroughs may lie in self-sensing smart coatings with dynamic thickness adjustment, potentially sparking a new revolution. In this era of precision and intelligence, mastering coating thickness will benchmark a nation’s advanced manufacturing prowess.

Dodaj komentarz

Twój adres email nie zostanie opublikowany.