In this article, we will discuss the four main machining targets for CNC tools and their properties.

What are CNC tools designed for?

1Turning: Turning is a machining process used to create cylindrical parts. CNC turning machines use a cutting tool to remove material from a rotating workpiece. The properties of a good turning tool include high hardness, toughness, and resistance to wear and heat.

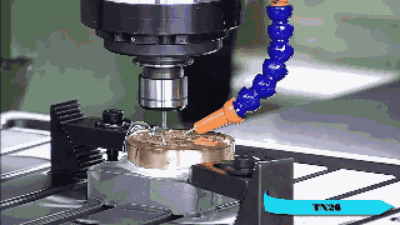

2Milling: Milling is a process that involves removing material from a workpiece using a rotating cutter. CNC milling machines are used to produce flat and complex shapes. The properties of a good milling tool include high rigidity, sharpness, and resistance to wear and heat. Meetyou carbide?is dedicated to producing high-quality ?? ?? ?, and our customers can freely request a quote and place orders on our website.

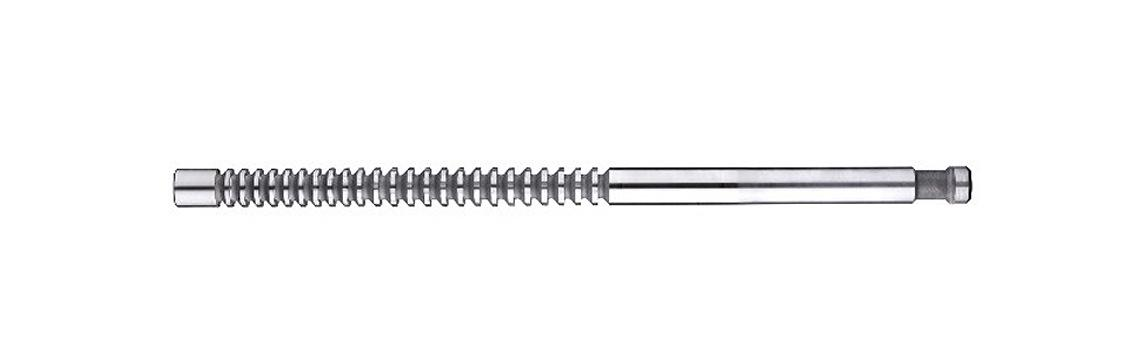

3Drilling: Drilling is a process used to create holes in a workpiece. CNC drilling machines use a rotating cutting tool to remove material. The properties of a good drilling tool include high toughness, sharpness, and resistance to wear and heat.

4Grinding: Grinding is a machining process used to produce smooth surfaces and tight tolerances. CNC grinding machines use abrasive wheels to remove material from a workpiece. The properties of a good grinding tool include high hardness, toughness, and resistance to wear and heat.

Main machining object types of CNC tools

1Box parts:

?? ??? ????? ?? ?? ???, ?? ?? ? ??, ?? ? ??? ?? ??? ?? ??? ?????. ??? ??? ?? ?? ??, ???, ??? ?? ? ?? ??? ?????. ?? ??? ????? ?? ?? ?? ??, ?? ?? ? ?? ?? ?? ??? ????? ???? ????? ??, ???, ??, ??, ??, ??? ??, ?? ? ?? ????? ?? ???? ?? ?? ?? ??? ?? ?? ???? ?? ??? ? ?? ??? ?????. ? ?? ???. ?? ??? ???? ??? ??? ?? ????? ??? ????? ?? ???? ?? ????? ??? ??? ? ?? ?? ?? ?? ? ?? ??? ??? ?????.

2Complex surface parts:

??? ??? ?? ??, ?? ???? ???? ??? ??? ???. ???? ?? ???? ??? ??? ???? ?? ???? ??????. ??? ???? ??? ?? ??? ???? ??? ??? ? ????. ??? ???, ?? ????, ??, ??? ?? ?? ??, ???? ? ?? ?? ???? ? ?? ?? ??? ?? ??? ?? ??.

3Special shaped parts and accessories

???? ??? ??? ???? ??? ???? ???? ?, ?, ?? ?? ???? ?? ??? ?????. ?? ?? ??? ??? ????? ???? ??? ??? ???? ??? ?? ???? ???? ??? ?? ??? ?? ????? ?? ?? ??? ???? ?????. ??? ??? ??? ?, ??? ??? ?? ???? ???, ?? ? ?? ?? ??? ??? ???? ?? ???? ?? ?? ????? ???? ?? ???? ???? ??? ??? ???.

4Disc, sleeve and plate parts:

?? ??? ??? ? ?? ?? ??? ??, ??? ?? ?? ??? ??? ?? ???, ??? ??? ???, ? ? ?? ?? ?? ??? ??? ?? ?? ??? ??? ?? ??? ?? ? ??? ??? ??? ??? ??? ?? ? ??? ?? ??? ??? ?? ??? ? ??, ??? ??? ?? ?? ??? ??? ????? ???.

Physical property matching between CNC tool material and machining object

????? ?? ??? ?? ?? ?? ??, ??? ?? ???? ?? ??? ??, ????? ?? ???? ?? ????? ??? ?? ??? ??? ?? ??? ??? ???? ???? ? ?????. ??. ????? ?? ???? ??? ?? ????? ?? ???? ??? ???? ???? ??? ???? ????? ?? ? ??? ???. ?????? ?? ????? ????? ?? ?? ?? ?? ???? ? ? ??? ???? ????. ?? ?? ?? ???? ???? ?? ?? ??? ?? ?????.

① ?? ???? ??? ???? : ????? ????? ?? 700 ~ 800℃; PCBN ??? 1300 ~ 1500 ℃???. ??? ?? ??? 1100 ~ 1200 ℃???. TiC(n)? ????? 900~1100℃; WC ?? ??? ?? ????? 800 ~ 900 ℃???. HSS? 600~700℃???.

② ??? ?? ??? ???? ??: pcd>pcbn>wc ?? ?? >tic(n) ?? ?? >hss>si3n4 ?? ??? >a1203 ?? ???.

③ ?? ????? ?????? ??? hss>wc? ????>tic(n)>A1203????>pcbn>si3n4????>pcd???.

④ ?? ????? ????? ?? hss>wc? ????>si3n4? ????>pcbn>pcd>tic(n)? ????>a1203? ???? ???.

???? ??? ????? ??? ?? ??

?? ?? ??? ?? ?? ?? ??? ?? ?? ??? ?? ?? ?? ??? ??? ?? ??? ??? ???, ?? ??, ?? ? ??? ?? ??? ?? ????? ??? ?????. ??? ?? ??? ?? ??? ??? ??? ??? ???? ? ?????.

① ??? ?? ??(? ??)? ?? ?? ??: pcbn> ??? > ???? >hss.

② ??? ?? ?? ??? ?? ?? ??: ??? > pcbn > ???? > ????? > hss.

③ ? ?? ?? ?? ??? ?? ??: ??, ????? >si3n4 ?? ??? >pcbn>a1203 ?? ???; ???? ?? A1203 ?? ??? >pcbn>sic>si3n4> ?????.

CNC ?? ?? ??

?? ? ????

?? ??? ??? ????? 60HRC ??? ??? ??? ???? ??? ???. ????? ?? ??? ??? ???? ????? ?????.

??? ??

??? ???? ???? ???? ?? ???. ??? ?? ??? ???, ?? ? ??? ??? ??? ?? ?? ? ??? ??? ???? ?? ?? ??? ??? ??? ???.

??? ? ????

??? ????? ??? ??? ??? ? ????. ???? ???? ???? ?? ?? ? ??? ???? ??? ??? ? ?????. ????? ???? ?? ?? ???? ?? ? ?? ???? ?? ??? ??? ??? ?? ??? ????.

In conclusion, CNC tools are versatile and can be used for a wide range of machining operations. The properties of a good CNC tool depend on the machining target and the material being machined. High hardness, toughness, sharpness, and resistance to wear and heat are key properties for CNC tools. By understanding these properties, manufacturers can choose the right tool for their specific machining needs.