The wear forms on valves

Based on the conditions and mechanisms of friction, wear can take various forms, with common types including abrasive wear, adhesive wear, fatigue wear, corrosive wear, and erosive wear.

Common parameters used to characterize material wear performance include wear volume, wear rate, wear depth, wear resistance, and relative wear resistance. The fundamental requirement for abrasion resistance is that the surface of the object must have high hardness (surface hardness should exceed the hardness of the abrasive). Additionally, it should exhibit good oxidation resistance at the operating temperature. The most effective way to control or minimize wear is to enhance material hardness and wear resistance.

Sintered tungsten carbide has high strength, a smooth surface finish, and a lower coefficient of friction compared to steel when used in conjunction with other materials. This significantly reduces contact surface frictional forces, effectively lowering operating torque.

Material features of carbide

Whole sintered carbide?is produced by high-temperature heating of a mixture of tungsten and carbon. The hardness of most tungsten carbides is very high, with microhardness second only to diamond. It has a melting point of 2870°C and a boiling point of 6000°C, with a relative density of 15.63 (at 18°C). It is resistant to decomposition at high temperatures and exhibits excellent oxidation resistance.

Field investigations indicate that tungsten carbide demonstrates wear resistance in situations such as abrasive wear, erosive wear, and abrasion, which is about 100 times higher than that of tool steel, stainless steel, iron, and brass. It has 2-3 times the rigidity of steel and 4-6 times the rigidity of cast iron and brass, with impact resistance similar to that of quenched tool steel.

The reason carbide is needed in valves

In conditions involving high temperature, high pressure, strong corrosion, and slurries or powders with solid particles such as in gasification and polycrystalline silicon, the sealing surfaces of conventional hard-sealed ball valves, V-port control valves, coal powder control valves, butterfly valves, and slide valves use carbides as the sealing materials for the valve disc and seat. However, due to the limitations of the sprayed tungsten carbide coating—thickness <2mm, hardness <60HRC, and coating adhesion to the substrate <1000psi—the spraying process is typically conducted under harsh conditions at temperatures as high as 10000°C. Valve lifespans are challenging to guarantee for 10,000 cycles, making it difficult to meet the long-term stable production requirements of systems handling coal chemical slurries and polycrystalline silicon powders.

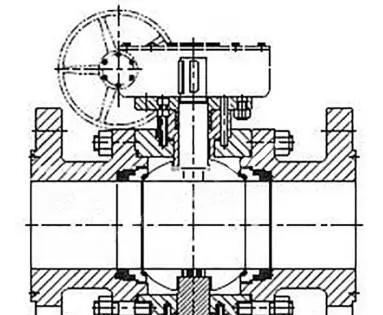

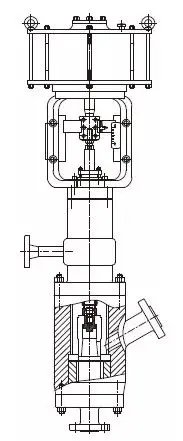

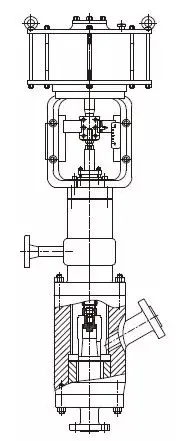

On the other hand, the strength of sprayed tungsten carbide mainly relies on the base material, and when the coefficients of thermal expansion of the two materials are significantly different, the usage is limited by temperature and cannot exceed 450°C. The valve performance has seen significant improvements with the adoption of integral sintered carbides for the valve disc and seat in new types of hard-sealed ball valves (Figure 1), V-port control valves (Figure 2), coal powder control valves (Figure 3), butterfly valves (Figure 4), and slide valves, addressing these challenges.

Fig1 Sealing ball valve

Fig2 control valve

(1) High Hardness: With a hardness greater than 80HRC, it can withstand the high-speed scouring of multiphase particle media such as water-coal slurry, coal powder, and silicon powder.

(2) High-Temperature Resistance: Capable of prolonged operation at temperatures up to 750°C, it is not limited by temperature in terms of strength, adhesion, and thermal expansion. This completely meets the requirements of high-temperature conditions, such as those encountered in coal chemical processes.

(3) High Pressure Resistance: The transverse fracture strength of integral sintered tungsten carbide reaches 4000MPa, more than 10 times the strength of conventional steel. It can operate long-term under working pressures up to 25MPa.

(4) Corrosion Resistance: Integral sintered tungsten carbide exhibits stable chemical properties. It is insoluble in water, does not react with hydrochloric acid and sulfuric acid, and is not dissolved even in aqua regia. This corrosion resistance satisfies the special requirements of industries such as coal chemical processing.

Fig3 Coal powder control valve

Fig4.?Butterfly valve

(5) Wear Resistance: The high hardness and stability of integral sintered tungsten carbide ensure excellent anti-wear properties for sealing components. This meets the special wear requirements of media such as coal powder and organosilicon (silicon powder particle hardness is 62HRC).

(6) Erosion Resistance: Conventional valves with sprayed tungsten carbide coatings on sealing surfaces often suffer severe erosion, exhibiting honeycomb patterns within a month under conditions of 250°C and losing functionality completely. In contrast, V-port control valves and coal powder control valves, which use integral sintered tungsten carbide as control components, have a lifespan of 12 months under 450°C (other conditions remaining the same). Disc valves and slide valves, subjected to more than 300,000 switching cycles, fully meet the long-term operational requirements of industries such as coal chemical processing for 8000 hours.

(7) High-Temperature Flexibility: Both the ball and seat are made of integral sintered carbides, with coefficients of thermal expansion ranging from 1/3 to 1/2 of conventional steel. This effectively prevents the common issue of valve sticking at high temperatures, ensuring excellent operational performance under high-temperature differential conditions.

(8) Low Friction: The use of sintered carbide?anti-wear pads not only extends the high-temperature lifespan of the pads but, due to their lower friction coefficient, typically only 1/3 to 1/2 of conventional paired materials. This significantly reduces frictional forces between components, lowering valve operating torque.

結(jié)論

Integral sintered carbide?possesses high strength, high hardness, a high melting point, stability, a low friction coefficient, wear resistance, erosion and cavitation resistance, and corrosion resistance. Manufacturing wear-resistant valve sealing components for demanding operating conditions has enhanced the applicability of valves, expanded their range of use, prolonged their operational lifespan, ensured various performance indicators, and met the development needs of the chemical industry.