Now with the development of economy, the development of CNC machining customization technology is becoming stronger and stronger. Many CNC machining customization industry is in a hot state at present, but in the factories that need processing, they know little about NC machining customization and do not know how to choose. Next, I’ll introduce it to you.

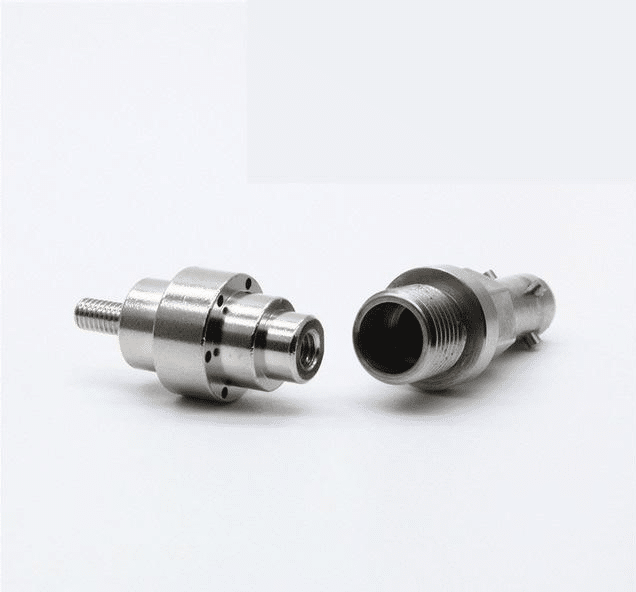

CNC is the abbreviation of NC machining, which is the process of material removal through precision machining. Precision machining, that is, precision machining, is processed by high-precision machine tools. The main method to realize precision machining of parts is to use high precision machine tools to process high precision parts. Using error compensation technology to improve the machining accuracy of high parts.

There are two main types of machining: manual machining customization and CNC machining customization. Manual processing customization refers to the method that machine operators process various materials by manually operating machine equipment (such as milling machine, lathe, drilling machine and saw).

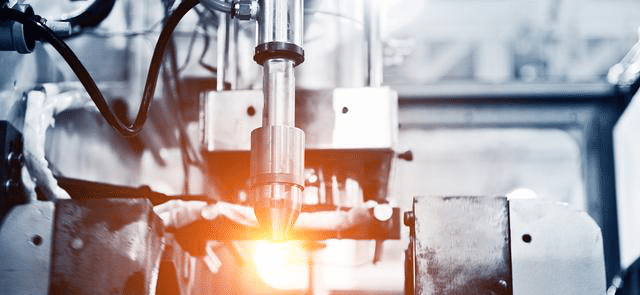

Manual processing is suitable for the production of small batch and simple parts. High precision machining (CNC machining customization) uses CNC equipment to perform mechanical operations, including machining center, powder machining center, WEDM equipment, thread cutting machine, etc.

In the process of changing from blank to finished product, the total thickness of the metal layer removed from the machined surface is called the total machining allowance of the surface. The thickness of the metal layer removed in each process is called the inter process allowance.

For rotating surfaces (such as outer circles and holes), the machining allowance is considered according to the diameter, so it is called symmetrical abundance (i.e. bidirectional abundance). In other words, the thickness of the metal layer actually removed is half of the machining allowance diameter. The machining allowance of a plane is actually a single edge allowance, such as the thickness of the metal layer to be removed.

The purpose of leaving machining allowance on the blank is to eliminate the machining errors and surface defects left by the previous process, such as cold hard layer, air hole, cinnabar layer, oxide on the surface of forging, decarburization layer, surface crack, internal stress layer after cutting and surface roughness. High working precision and surface roughness are mentioned.

The size of machining allowance has great influence on machining quality and production efficiency. Excessive machining allowance will not only increase the processing workload and reduce productivity, but also increase the consumption of materials, tools and power, thus increasing the processing cost.

The machining allowance is too small to eliminate all kinds of defects and errors in the previous process, and can not compensate the fixture error in the process of the process, thus resulting in waste products. The principle of selection is to ensure the quality and make the allowance as small as possible. Generally speaking, the more you finish, the less you have left.