Wear and deformation caused by the intense flow of the deformed metal on the die surface. Sometimes, the die cavity surface is scratched, abraded, or even adhered to, which easily causes dimensional errors and scrapping of the die, resulting in poor product quality.

The die cavity is easily deformed due to the relatively insufficient yield strength of the matrix material.

After continuous and repeated stress, especially in areas with stress concentration, the fatigue life of the alloy steel is relatively low, leading to fatigue failure as the number of heading operations increases.

Therefore, in addition to further improving the life of alloy steel dies, there is a widespread demand for a new material that is both wear-resistant and has good toughness to adapt to the development of the cold heading industry.

Test Results and Application Assessment

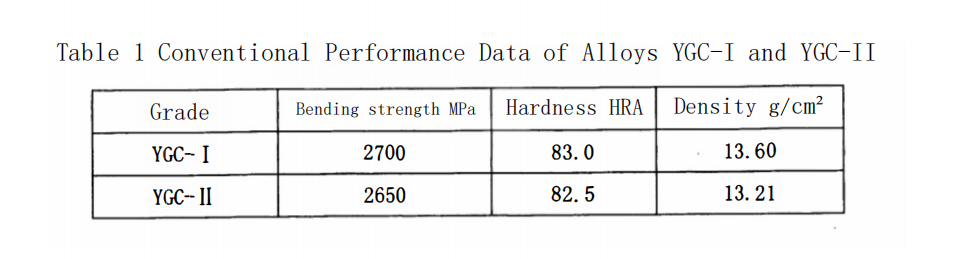

To expand the application field of cemented carbide and meet the urgent demand of steel ball factories for large-sized steel ball cemented carbide dies, based on our long-term work experience and domestic and foreign data collection, we finally selected a specially made coarse-grained WC powder, supplemented by an appropriate binder phase, to formulate YGC-I and YGC-Ⅱ coarse-grained cemented carbides (YGC-Ⅱ has a higher binder phase content than YGC-I). The conventional performance data of YGC-I and YGC-Ⅱ are shown in Table 1.

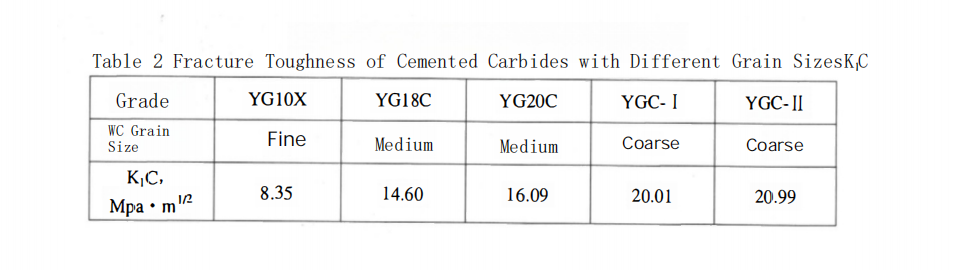

To study the effect of different particle sizes of WC powder on the fracture toughness of cemented carbide, fine-grained cemented carbide YG10X, medium-coarse grained cemented carbide YG18C, and YG20C were also prepared.

The fracture toughness of fine-grained, medium-coarse grained, and super-coarse grained cemented carbides with three different WC particle sizes was measured, and the results are shown in Table 2. It can be observed from Table 2 that as the WC particle size changes from fine-grained to medium-coarse grained and then to coarse grained, the fracture toughness of the alloy increases significantly, or even doubles. Even within the same particle size range, the fracture toughness of the alloy also increases with the increase of the binder phase content. This indicates that there are two ways to improve the fracture toughness of the alloy: first, by selecting coarse-grained WC powder, and second, by increasing the binder phase content of the alloy.

Selected YGC-I and YG10X samples were used to take scanning electron microscopy (SEM) fracture photos. Figure 1a shows the SEM fracture photo of YGC-I, and Figure 1b shows the SEM fracture photo of YG10X. Careful observation of the SEM fracture photos reveals that YGC-I has coarse grains and a thick binder phase layer, with cracks extending along the binder phase, resulting in mostly intergranular fractures and thus a higher fracture toughness K?C. In contrast, YG10X has very fine grains and a very thin binder phase layer, with mostly transgranular fractures, leading to a lower fracture toughness K?C. This indicates that the trend in fracture toughness values of carbides with different grain sizes is consistent with the conclusions drawn from the analysis of SEM fracture photos.

The aforementioned coarse-grained cemented carbide developed was applied to cold heading larger specification steel balls φ17.4625 and φ19.05. After being used on a Z32-28 machine at a certain factory, the usage data show that the coarse-grained cemented carbide is capable of stamping larger specification steel balls, and its die core life is more than 8 to 10 times longer than that of GCr15. This not only expands the application scope of cemented carbide but also provides the possibility for the bearing industry and standard parts industry to adopt carbide dies with larger heading forces. Moreover, due to the significant increase in die life, it brings about considerable economic benefits.

Conclusione

1.Selecting specially made coarse-grained WC powder and correspondingly increasing the binder phase content of the alloy is an effective way to improve the fracture toughness of cemented carbide.

2.SEM fracture analysis indicates that coarse-grained cemented carbide fractures are mostly intergranular, resulting in a higher fracture toughness K?C, while fine-grained cemented carbide fractures are mostly transgranular, leading to a lower fracture toughness K?C.

3.The usage results show that the life of coarse-grained cemented carbide die cores is more than 8 to 10 times longer than that of GCr15.

4.In summary, for the stamping of larger specification steel balls, choosing coarse-grained cemented carbide is a reasonable option.

Lascia un commento

Il tuo indirizzo email non sarà pubblicato.