The main function of a rotary?bur?is to cut, shape, grind, and remove burrs, sharp edges, and excess materials (deburring). It can quickly remove any excess material that may exist on the workpiece. carbide?rotary burrs are often used in the process of removing uneven edges on the surface.

In their most basic form, popular cuts may be broken down into two categories: single cut carbide burr, double cut carbide burr,

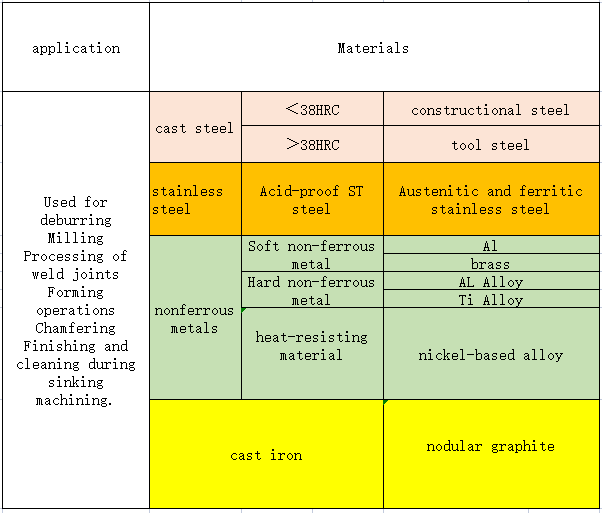

APPLIED MATERIALS FOR CARBIDE BURRS

Burrs made of tungsten carbide may be used on a wide variety of materials, including aluminium, steel, and forged iron. Carbide burrs for metal are?available?in a wide variety of sizes and forms, including those that are round, cylindrical, or oval and have variable diameters.

MAIN SHAPES?of CARBIDE?BURRS

The following is a list of the most frequent shapes of carbide burrs:

Cylinder shape

Cylindrical rotary tips are used for cutting, trimming, and deburring of metals, wood, and plastics. Circular rotary burrs are particularly suitable for trimming and shaping curves and arcs.

Cone shape

This type of rotary burr?has a cutting surface that gradually tapers from the base to the top. This shape makes the taper shape rotary burr?particularly suitable for trimming and shaping holes, as well as chamfering the inside of holes.

Flame shape

When cutting materials with round edges, use a carbide tip shaped like a flame. The flame form of carbide burrs is intended for use in deburring and polishing elliptic surfaces on steel dies, forgings, castings, and metal patterns.

Tree shape

This rotary tip looks like a tree, but has a sharp tip at the top. This type of tool can easily machine to lengthy and compact positions that are inaccessible to most other shapes. Tree shaped rotary tips are used for deburring and completing deep contour surfaces of steel molds, molds, and metal patterns. They can also be used to repair damaged parts on molds caused by burrs.

Oval shape

Elliptical carbide burrs can effectively remove circular edges on the workpiece handed to you. Elliptical carbide drill bits are used for surface deburring and polishing of steel molds, forgings, castings, and metal patterns. The cross-section of these tips is elliptical. They are used to handle difficult fillet welds.

Ball shape

Deburring, circular bottom holes, curved grooves, and curved metal and material surfaces are some applications for designing spherical rotary burrs. In addition, you can use them to widen or lengthen small holes to handle hard fillet welds. Sphericity enables smooth machining of all circular edges of the workpiece and preparation for brazing the workpiece.

APPLICATIONS OF CARBIDE BURRS

Rotary tips are essential tools for fitters and repair workers. Their main applications include:

1Precision machining of various metal molds and cavities, such as shoe molds.

2Carving on metal and non-metal materials for craftwork and art pieces.

3Cleaning off tips, flashes, and weld seams on castings, forgings, and welded parts, commonly found in machine foundries, shipyards, and automotive factories.

4Chamfering, rounding, and grooving of various mechanical parts, pipe cleaning, and precision machining of internal hole surfaces of machine parts, commonly performed in machine shops and repair workshops.

5Polishing and finishing of impeller passages, commonly done in automobile engine factories. At our company, Meetyou, we offer versatile carbide rotary burrs. Please feel free to consult our online customer service to select the carbide rotary burr?that meets your specific needs.

PRINCIPLES FOR SELECTING CARBIDE ROTARY BURRS

Selection of rotary burr shape

The cross-sectional shape of the carbide rotary tips should be selected based on the shape of the workpiece to be burrd, ensuring a proper fit between the two. When filing internal curved surfaces, a half-round burr or round burr (for small diameter workpieces) should be chosen. For filing internal angular surfaces, a triangular burr is appropriate. For filing internal right-angle surfaces, flat burrs or square burrs can be used. When using a flat burr to burr internal right-angle surfaces, care should be taken to position the narrow face (without teeth, called the safe edge) of the burr next to one of the internal right-angle surfaces to avoid scratching or damaging that surface.

Selection of burr tooth thickness

The coarseness of the tip teeth should be chosen based on the amount of material to be removed, machining precision, and the nature of the material. Coarse-tooth burrs are suitable for processing workpieces with large material allowances, low dimensional accuracy, large geometric tolerances, high surface roughness values, and soft materials. Conversely, fine-tooth burrs should be chosen for the opposite conditions. When using burrs, the selection should be based on the required machining allowances, dimensional accuracy, and surface roughness of the workpiece.

Selection of size specifications for alloy burrs

The size and specifications of the carbide rotary burr should be selected based on the size of the workpiece and the machining allowances. For larger workpiece dimensions and larger machining allowances, a rotary burr with larger size specifications should be chosen. Conversely, for smaller workpiece dimensions and smaller machining allowances, a rotary tip with smaller size specifications should be selected.

Selection of burr tooth patterns

The tooth pattern of the tungsten steel grinding head burr?should be selected based on the nature of the material being burrd. When filing soft materials such as aluminum, copper, and mild steel, it is preferable to use a single-tooth pattern (milling tooth) burr. The single-tooth pattern burr?has a larger rake angle, smaller wedge angle, larger chip clearance, and sharp cutting edge, making it less prone to chip clogging and ensuring efficient cutting.