Let ‘s just cut into the case.

??? ???? ??????? ???? ???

????? ??????????? ??????? ?? ???? ??????????? ?? ???? ??????????? ??? ?????? ??? ???? ?? ???? ???? ??? ???? ?? ?????? ??, ????? ?? ?? ??? ?? ?????? ?? ????? ?? ???? ???? ???? ??, ???? ???? ????? ????????? ?????? ?? ??????? ?? ??? ?? ????? ?? ?????????? ???? ???? ???? ??? ????? ??, ??? ???? ??????? ?????????? ???? ?? ?????? ?? ????????? ???? ?? ??? ???? ?? ?????? ???? ??, ?? ????? ?? ??? ???? ?? ???? ?????? ?? ?????? ???? ??? ????? ????? ?? ??? ?? ????? ??????????? ????? ?? ?????? ???, ????? ??? ??? ??????? ?? ??? ??????????? ????? ?? ?????? ?? ??????? ???? ?? ?????? ??? ??????? ???????? ????? ?? ?????, ?????????? ????? ?? ????? ??????????? ?????, ????? ????? ?? ???? ??? ?? ????-????? ????? ?? ????? ??? ???? ??????? ??????? ?? ??? ??????????? ???? ???? ???

??? ???? ?? ???? ???? ??? ???? ????? ???? ???? ??, ?? ??? ????? ??????????? ??? ???? ??? ????? ??????????? ????? ?? ???? ?? ??? ????? ?? ??? ????? ?? ??? ?????????? ??????????????? ??? ?? ?? ??, ????? ?? ???? ????? ?? ????????? ?????????? ??? ?? ????? ?????????? ???? ??? ??? ????? ?? ???? ??????? ?? ??? ?????????? ?????? ?? ???? ?? ?????? ?? ???? ???? ???? ??, ?? ??? ???? ???? ??????? ??? ???? ??? ????? ??????????? ??? ??? ?? ?? ????? ?? ????? ??? ????? ??????????? ????? ???? ??????????, ???? ??????, ???? ???????? ?? ?? ??? ?? ??? ?? ????? ??????? ????? ??? ?? ?????? ??? ?? ???? ?? ????? ???????? ?? ???? ?????? ?? ??????? ??? ????? ???? ???? ??? ???? ???????? ?? ???? ???????? ?? ????? ???, ?? 30%-50% ??????? ?? 40%-80% ????? ?? ??? ?? ???? ??? ?? ????? ?? ???????? ?? ??? ?? ????? ??? ?? ????? ?? ???? ??? ??????? ???, ?????????, ??????, ???????????????, ????? ?? ?????, ?????? ??????, ?????????, ??????, ????? ?? ???? ???????? ????????? ??? ????? ??????????? ????? ?? ?????? ??? ?? ????? ???? ??? ??, ?? ???? ????????? ?? ?????? ????? ???? ????? ??? ????????? ?????????? ?????????? ?????? ??? ?? ?? ?? ??? ??? ??????? ?? ???????????? ?? ?????? ?? ?????????, ??????????, ????? ??????? ?? ???? ???????? ??? ???????? ?? ??? ?????? ?????????? ?? ?????? ????? ?? ???, ??? ???? ??????? ??????? ????? ????-???? ???? ?? ????? ???????? ?? ??? ??????? ?? ????? ?? ???? ?? ?? ??? ????? ??????????? ??? ??????? ???????????, ??????? ???????????, ???????? ??????????? ?? ?????? ??????????? ????? ????

??? ???? ??????? ????????? ?? ???

1. ?????? ????? ??? ??? ???? ??????? ?????? ???? ????? ????? ?? ??? ???? ????????? ?????? ?? ????? ???? ??, ?? ?????????? ?? ?? ???? ?? ??????? ?? ????? ??? ????? ?? ???? ??? ????? ??????????? ?? ??????? ????? ?? ?? ??? ?? 80% ?? ???? ?? ????? ???? ??? 2. ??????? ????? ?? ????? ?? ???? ??? ???? ??????? ?? ????? ???? ???? ????????? ??? ????? ???? ?? ??? ????????? ???? ???? ??, ?????? ??? ?? ??????? ??? ??? 3. ????? ??? ???????? ?? ????? ?????? ???? ??? IT7-IT8 ?? R0.2-R0.6 ?? ????? ???? ???? ?????, ??? ???? ??????? ?????? ??????? ????? ?? ???? ?? ??? ?????? ????? ???? ??, ?? ???? ????? ??? ?? ???? ???? ?? ????? ?? ???????? ???? ??? 4. ??? ???? ??????? ?? ??? ????? ?? ???????? ????? ??? ????? ????, ??? ??? ???? ?? ??? ???? ?? ???? ????, ?? ????? ?? ???? ?? ???? ????? ??????????? ????? ?????, ???? ????? ??? ?? ????? ??? ????? ?? ???? ???? ???? ??? ???? ?????, ???? ??? ???? ??????? ????????? ????? ?? ??? ?? ???????? ???? ??? ???? ?? ?? ???? ????? ??? ????? ?? ???? ??? ?????, ??? ??????? ?? ??? ??? ???? ??????? ????????? ?? ???? ???? ?? ???? ?? ???? ????? ????? ?????? ????? ???? ?? ???????? ???? ??? ??? ????? ?? ???? ????? ???? ????? ?? ??????? ???? ?? ???????? ??? ??? ???? ??????? ????????? ?? ???, ?? ???? ???? ????? ?? ????? ???? ???? ???? ?? ???? ??? 5. ???? ????????, ???? ?? ????? ???, ???? ?????? ????, ?????? ???? ?? ??? ?? ?????? ?????? ????? ?? ??? ???? ????? ?????, ??????? ????? ??????? ??? 6. ????? ?? ???? ?? ?? ???? ??????? ??? ???? ??????? ????????? ??? ????? ??? ?? ?????, ????????? ??? ????? ????, ???? ???? ????? ?? ?????? ?? ?? ???? ?? ???? ???????? ???? ??????? ?? ???? ???? ??????? ?? ????? ???? ?? ????? ???, ???? ????? ?? ???? ???? ?? ?? ??? ?

??? ??? ???? ???

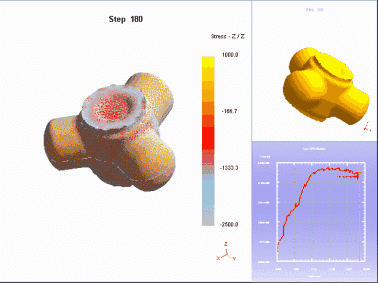

????? ?????? ??????? ?? ??? ????? ???????? ????????? ??? ?? ???? ????? ?????? ?? ???? ?????????? ?? ??? ?? ??????????? ??? ?? ?? ??? ?? ?? ?????? ?? ?????????? ???? ?? ?? ????? ?? ?? ?????? ?? ??? ???? ?? ????????? ?????? ?? ????? ???? ?? ?? ???? ?? ?????? ?? ???? ?? ?????????? ?? ????????? ?? ?????? ????? ??, ?? ?????? ?????? ????? ?? ????? ????? ?? ??????? ???? ??? ???? ????????? ???? ?????, ??????, ??, ???????, ??? ?? ???? ?? ??????? ?? ??? ????? ?????? ????????? ???? ??????? ??? ????? ?????? ????????? ??? ???????? ???? ???? ??????? ????? ????? ????? ?????? ???? ??? ??? ??????? ???? ???? ??, ?? ???? ???? ?????? ????? ?? ????? ????? ?? ????? ???? ?? ???? ??? ???? ???? ?????????, ????? ?????? ?? ????????, ??????? ?? ??? ?? ?? ????, ??????? ???? ?? ?? ???? ?? ??? ???? ?? ?????? ??? ????? ???? ?? ????, ???????? ??????? ???, ????? ??? ?? ???? ????????? ?? ??????? ??? ??? ??? ??? ????????? ?? ???? ?? ???? ????? ???? ???? ??? ???-?????? ????? ?????? ???? ?????? ???????? ???? ???? ????????? ?????? ????? ??? ?????? ?? ???

????? ?????? ????????? ?? ???

1. Cold upsetting is carried out at room temperature. Cold heading can improve the mechanical properties of metal parts. The tensile strength of cold upsetting is about 10% higher than that of cutting, and some can even be increased by 20%. This is because the metal fibers of cold heading products will not be cut off, the internal structure of the metal will be compacted, and accompanied by the existence of work hardening, so the mechanical properties of the metal have been improved. 2. Cold heading process can improve material utilization rate. Taking the cold heading bolt as an example, the material utilization rate of the new technology “concave” hexagonal head bolt can reach more than 99%. Except for the loss of material head and tail, no cutting has been achieved. For cutting, the material utilization rate is only 40%. The material utilization rate of cold heading nut can also reach about 80%, while that of cutting nut is only 54%. 3. Cold heading process can greatly improve productivity. For example, compared with the original cutting process, the productivity of cold heading nut is increased by 25-30 times. 4. Because of the use of multi-station cold heading machine, all processes are processed simultaneously on one machine tool, which reduces the investment of equipment, reduces the production site occupied by equipment, reduces the transportation of semi-finished products between different processes, especially reduces the labor intensity of workers, and improves the working conditions. 5. Cold heading process can improve product surface finish and ensure product accuracy. For mass production of bolts, nuts and so on, the accuracy can be fully guaranteed.

Is cold heading the same as cold extrusion? What’s the difference?

????? ???????? ?? ????? ??????????? ??? ??? ?? ???? ???????????? ??? ?????? ????????? ??, ????? ?????? ??? ??? ??? ????? ??? ???? ??????? ?? ???????? ?????? ?? ??????? ?? ?? ????? ??????? ?????? ??? ????? ???? ???? ??? ????? ??????????? ???? ??????? ?? ??????????? ?????? ?? ??????? ?? ?? ????? ??????????? ?? ?? ??????? ???????? ??? ????? ????????, ???? ??????????? ?? ?? ???? ?? ????? ??? ???? ?????? ???, ????? ????? ?? ????????? ???, ?????????? ??? ?? ??? ??? ?????? ???? ?? ??? ???? ??, ?? ??? ????? ??? ??? ??? ???? ??????? (??? ???? ???????) ?? ??????? ??? ???-????? ?????????? ????? ??? ?????? ????? (???-?????? ?????) ??? ??? ?????? ?? ??? ???? ??????? ????? ??? ?????????? ???? ?? ????? ?? ??? ??? ?????? ??, ???? ???? ?? ????????? ??? ???? ??????? (??? ?? ???? ???? ???????) ???