Get to know geometric features of twist drills

Before purchasing twist drills, we need to first learn about several important geometric features of twist drills. These geometric features can be divided into the following three parts:

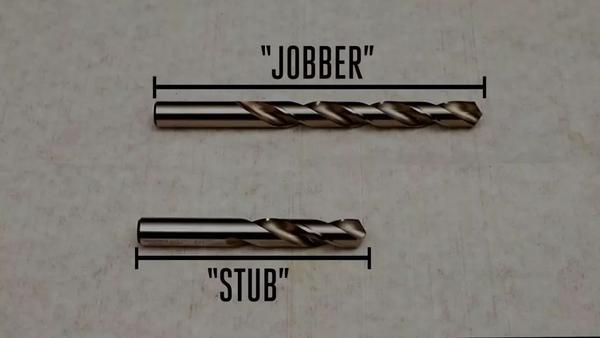

Twist drill length

The ratio of length to diameter is called the length-to-diameter ratio, and the smaller the length-to-diameter ratio, the better the rigidity. Choosing a drill bit with a cutting length that is just enough to evacuate chips and has a short overhang can improve the rigidity during machining, thereby increasing the tool’s service life. If the cutting length is not enough, it may damage the drill bit.

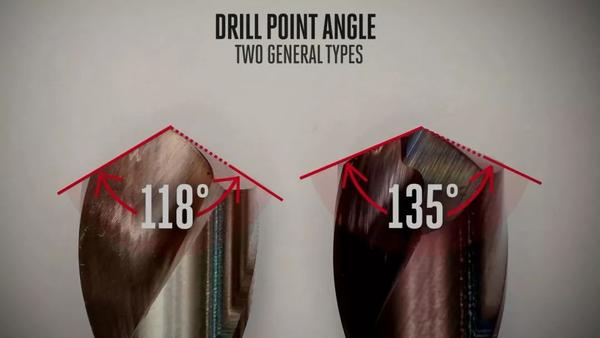

Twist drill point angle

The 118° twist drill point angle is the most common in machining and is usually used for soft metals such as low carbon steel and aluminum. The design with this angle usually does not have a self-centering function, which means that it is inevitable to first machine a centering hole. The 135° drill point angle usually has a self-centering function, and because it does not require a centering hole, drilling a separate centering hole will no longer be a necessary step, saving a lot of time.

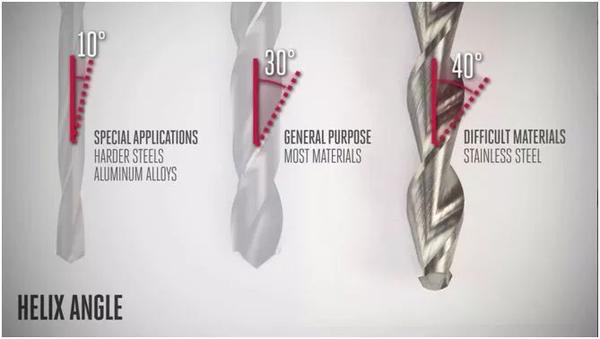

Twist drill helix angle

For the vast majority of materials, a 30° helix angle is a very good choice. However, for environments that require better chip evacuation and higher cutting edge strength, drill bits with smaller helix angles can be selected. For materials that are difficult to machine, such as stainless steel, a design with a larger helix angle can be chosen to transmit torque.

Choose right drill materials for your work piece

Common twist drill materials consist of the following 3 types.

HSS(High Speed Steel)

High Speed Steel has been used as a cutting tool material for over a century since 1910. It is currently the most widely used and also the cheapest cutting tool material. HSS drill bits can be used on both hand drills and more stable environments like drill presses. Another reason for the enduring popularity of HSS may be that tools made of this material can be repeatedly sharpened. Because it is inexpensive, it is not only used to grind into drill bits, but also has a wide range of applications in turning tools.

High Speed Steel with Cobalt

High speed steel with cobalt has better hardness and red hardness than high speed steel. The improvement in hardness also increases its wear resistance, but at the same time sacrifices some of its toughness. Like high speed steel, they can both be sharpened to increase their lifespan.

CARBIDE

Carbide is a type of composite material made of a metal base and other materials used as a binder, which is sintered through a series of complex processes such as thermal and isostatic pressing, with tungsten carbide as the matrix. Compared to high-speed steel, carbide has greatly improved hardness, red hardness, wear resistance, and other properties, making it an ideal material for improving the performance of spiral drills. However, the cost of carbide tools is also much higher than that of high-speed steel.

Choose a suitable coating for your twist drill based on your budget

Sin recubrimiento

Uncoated tools are the cheapest and are usually used for materials such as aluminum alloys and low carbon steel that are relatively soft.

Black oxide coating

The oxide coating can provide better lubrication than uncoated twist drills, and it also has better anti-oxidation and heat resistance properties. The service life can be increased by more than 50%.

Titanium nitride coating

Titanium nitride is the most common coating material on twist drills and is not suitable for materials with high hardness or high processing temperatures.

Titanium carbonitride coating

Titanium carbonitride is developed from titanium nitride and has higher heat resistance and wear resistance. It is usually purple or blue. This coating can be used on twist drills to process cast iron materials.

Aluminum titanium nitride coating

Aluminum titanium nitride is more heat-resistant than all the above coatings, so twist drills with this coating can be used in higher cutting environments, such as processing high-temperature alloys. This type of coating is also suitable for processing steel and stainless steel. However, since it contains aluminum, a chemical reaction may occur when processing materials containing aluminum, so it should be avoided.

In general, twist drills with cobalt and titanium carbonitride or titanium nitride coating are a more economical solution.