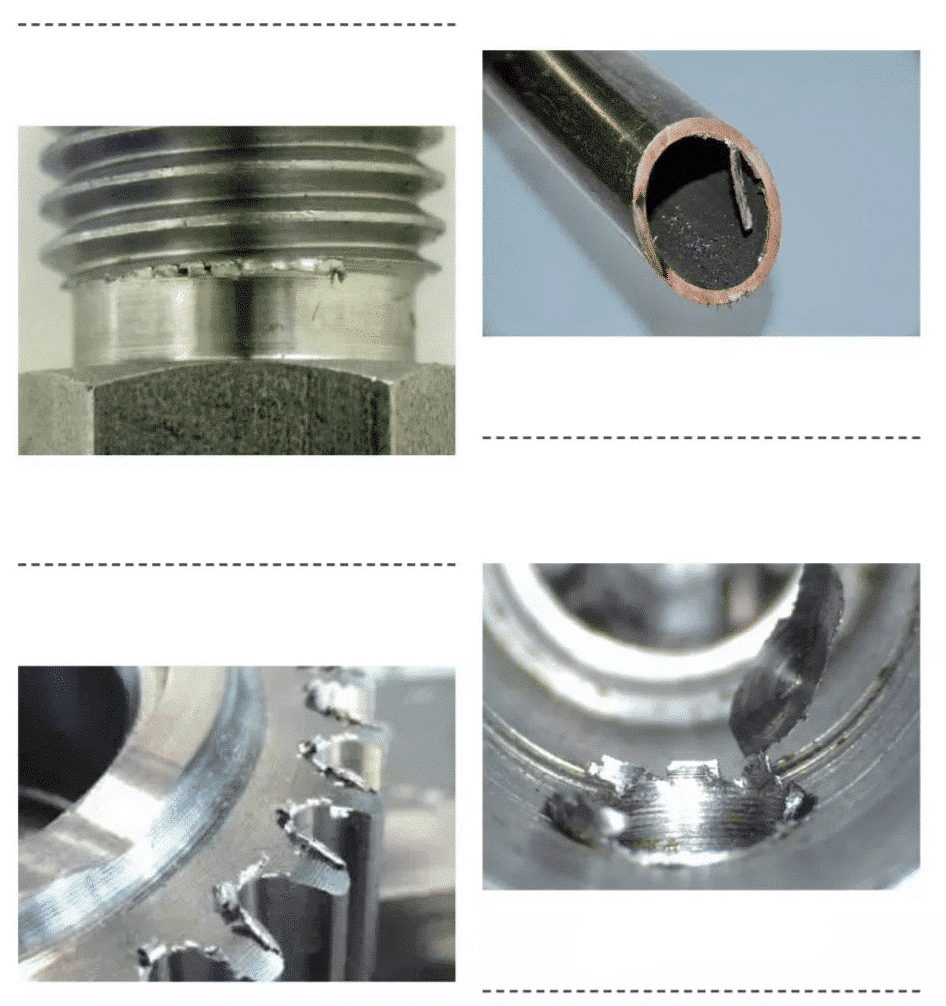

Burr in metal processing is a common problem, such as drilling, turning, milling, plate cutting.

One of the hazards of burrs is easy to be hurt. In order to remove burrs, a second operation called deburring is usually required. Three deburring and edge finishing of precision parts may account for 30% of the cost of finished parts. In addition, the second finishing operation is difficult to automate, so burrs really can become a very difficult problem.

How to Deal with Burrs

Chemical deburring

Chemical deburring is a process using chemical energy. Chemical ions will adhere to the surface of parts, forming a film with high resistance and low conductivity to protect the workpiece from corrosion. Because the burr is above the surface, it can be removed by chemical action. This deburring method is widely used in the fields of pneumatic, hydraulic and construction machinery.

Deburring at High Temperature

Firstly, the parts that need deburring will be put into the tightly sealed chamber, and then the whole part will be fed into the hydrogen-oxygen mixture with a certain pressure. Ignition will explode the mixture gas, release heat, and burn the burrs of the parts without harming the parts.

Burr removal by rolling

The parts and abrasives are put into the closed drum together. During the rotating process of the drum, the dynamic torque sensor, parts and abrasives are grinded together to remove burrs. Abrasives can be made of quartz sand, sawdust, alumina, ceramics, metal rings, etc.

Hand deburring

This method is more time-consuming and laborious than the traditional one. Mainly through manual steel file, sandpaper, grinding head and other tools for grinding. Now the most commonly used trimming knife in production.

Technological deburring

Edge inverted circle can refer to all the actions of removing the edges of metal parts. However, it is usually associated with the radius at which the edge of the part is created.

Corner circle

Instead of simply removing sharpness or burrs, the edge of a metal component is broken to improve its surface coating and protect it from corrosion.

The edge rounder includes:

Rotary setback: suitable for laser cutting, stamping or machining parts edge.

Manual grinding machine

It’s suitable for metal processing projects requiring grinding and edge rounding or deburring.

Burrs in Milling Parts with Special Difficulties

In milling parts, deburring is more complex and costly, because there are many burrs in different positions of different sizes. At this time, it is particularly important to select the right process parameters to minimize the burr size.

Factors Influencing Burr Formation in End Milling

1. Milling parameters, milling temperature and cutting environment have certain effects on burr formation. Some main factors, such as feed speed, milling depth and so on, affect burr formation through plane cut-out angle theory and tool-tip exit sequence.

2. The better the plasticity of the workpiece material, the easier the burr will be formed. In the end-milling process of brittle materials, if the feed rate or plane cut-out angle is large, it is conducive to burr formation.

3. When the angle between the end face and the machined plane is larger than the right angle, the burr formation can be restrained due to the increase of the supporting rigidity of the end face.

4.The use of milling fluid is beneficial to prolong tool life, reduce tool wear, lubricate milling process, and then reduce burr size.

5.Tool wear has a great influence on the formation of burrs. When the tool wear reaches a certain degree, the arc of the tool tip increases, not only the size of the burr in the exit direction of the tool increases, but also the shape burr in the cutting direction of the tool.

6.Other factors such as tool materials also have a certain influence on the formation of burrs. Under the same cutting conditions, diamond cutting tools are more conducive to inhibiting burr formation than other cutting tools.

Effective Treatments for Burr

1.Compress the space of burr as much as possible

It is an effective method to restrain the burr produced when the knife is withdrawn and eliminate the space of burr. For example, chamfering can be used to reduce the space before withdrawing the knife.

2.Using appropriate cutting conditions to restrain burrs

In order to minimize the cutting residual, the most suitable cutting tools and cutting conditions must be selected. Choose tool with large front angle and sharp cutting edge. Increase cutting speed and improve cutting characteristics. Especially in finishing cutting, the minimum cutting depth and feed must be adopted.