Main Preparation Techniques for Micro-Nano Cemented Carbide Powders:

1.Low-Temperature Reduction Decomposition Method

This method is an improved version of the conventional reduction carburization method to prepare micro-nano cemented carbide powders. It uses a low-temperature hydrogen process to reduce tungsten acid, tungsten oxide, or tungstic acid to micro-nano-scale tungsten powder, followed by carburization of the tungsten powder to micro-nano-scale WC powder at low temperatures.

2.Mechanical Alloying (MA)

This is a traditional method using mechanical force for the chemical synthesis of micro-nano cemented carbide powders. It involves placing a certain proportion of elemental powder mixtures in a ball mill jar and subjecting them to high-energy ball milling under an inert atmosphere for a long time. The powder particles undergo repeated grinding, breaking, extrusion, cold welding, and low-temperature solid-state chemical processes under the action of mechanical force, resulting in alloy powders with uniform composition and structure.

3.Spray Drying Method

Also known as thermochemical synthesis, this is currently the main method for industrial mass production of WC-Co composite powders. The process was developed by L.E. McCandlish and B.E. Kear of Rutgers University and has been patented. The Nanodyne Company in the United States uses this process to produce nanoscale WC-Co powder with a particle size of 20~40nm. The process involves mixing ammonium metatungstate [(NH?)?(H?WO??O?o)·4H?O] aqueous solution with cobalt chloride (CoCl·nH?O) to form an original solution, which is then atomized and dried to form a uniformly composed, fine mixture of tungsten and cobalt salts, followed by reduction and carburization in a fluidized bed to obtain nanophase WC-Co powder.

4.Gas Phase Reaction Method

This method uses the principle of gas-phase chemical reaction deposition to produce powders. It involves evaporating and vaporizing metals or alloys in equipment and reacting with active gases at certain temperatures to produce metal compounds, which are then condensed to obtain micro-nano-scale compound powders.

Experimental Method

High-purity cobalt powder and 0.8μm tungsten carbide powder were used as raw materials, mixed in a WC-10%Co ratio, and subjected to high-energy ball milling with a ball-to-material ratio of 9:1 using a QM-IF type planetary ball mill. The ball milling time was set at 24 hours per interval, with milling times of 24, 48, 72, and 96 hours. The particle size of the milled powder was measured using the Fsss method and X-ray diffraction. The powder samples with different ball milling times were then pressed and sintered under the same conditions to prepare cemented carbide specimens. Subsequently, strength and hardness tests were conducted, along with metallographic analysis.

Results and Analysis

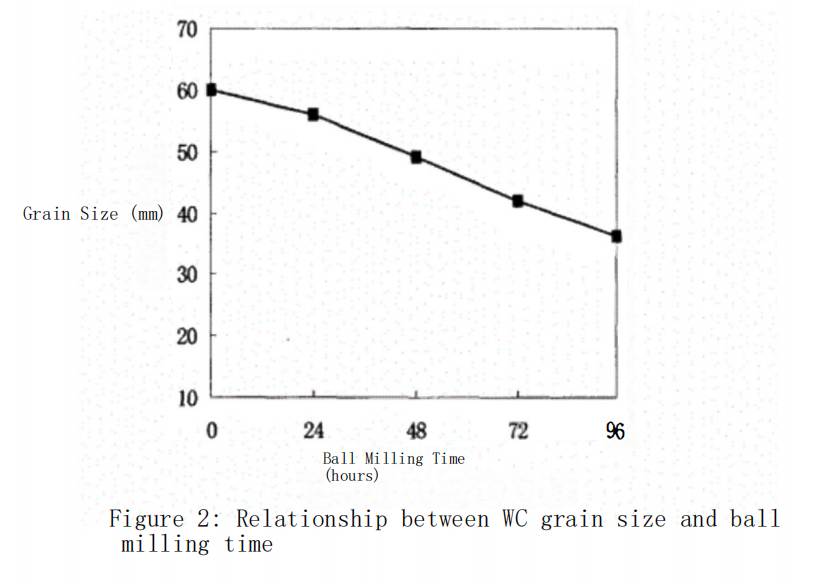

The Influence of Ball Milling Time on Powder Particle Size and Grain Size

Table 1 shows the measured Fsss particle sizes. It can be seen that the powder particle size decreases with the extension of ball milling time but becomes coarser after decreasing to a certain extent. However, the grain size continuously decreases. Powder particles and grains are different concepts. Particles consist of multiple grains encapsulated by cobalt powder. As ball milling progresses, while powder particles break, cold welding can also occur between the cobalt on the particle surfaces. Therefore, when ball milling reaches a certain degree, particle agglomeration exceeds breaking, leading to an increase in particle size, which eventually maintains a certain equilibrium state. The measured grain size is usually WC grains, which are brittle phases and easily broken during ball milling. Due to the encapsulation by cobalt powder, it is difficult for WC grains to cold weld, so the grain size continuously decreases.

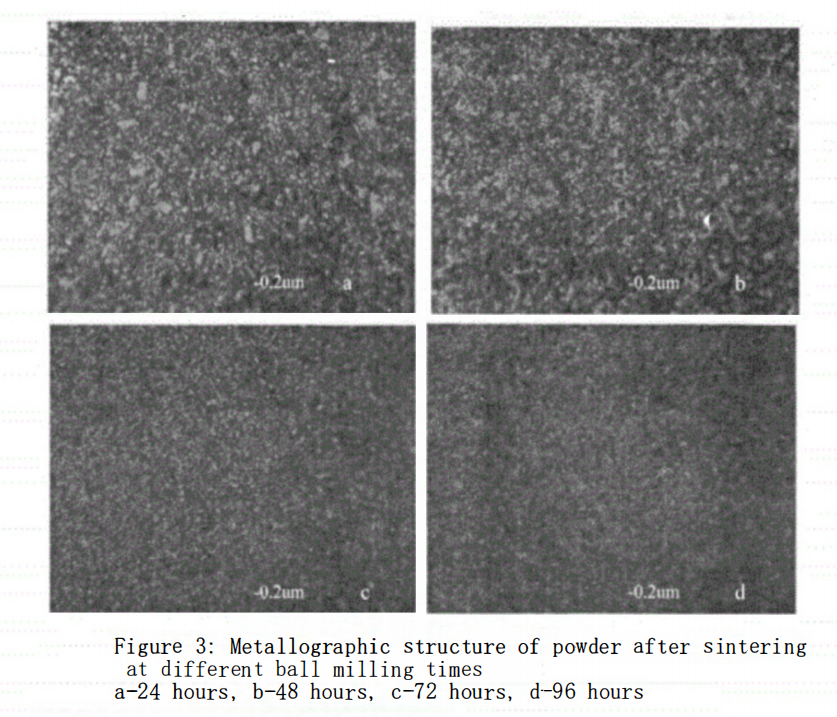

Microstructure After Sintering

Figure 3 shows the metallographic structure obtained after sintering, clearly indicating the influence of ball milling time on the grain size, shape, and distribution. As the ball milling time extends, the grains in the sintered body are significantly refined, tend to be uniform in size, and the WC grains are more dispersed. This is due to two factors: first, the WC grains themselves are refined and homogenized through ball milling, indicating that ball milling not only breaks the WC grains but also homogenizes them; second, it is formed during the sintering process. The sintering process only coarsens the particles and causes non-uniformity due to abnormal grain growth, which typically becomes more severe with longer ball milling time, as ball milling can cause lattice distortion, promoting abnormal grain growth. However, the results of this experiment do not show this; instead, the grain size tends to be more uniform with the extension of ball milling time. Clearly, the homogenization of WC grains is due to the effect of ball milling. This demonstrates that high-energy ball milling can refine and homogenize WC grains.

The Effect of Ball Milling Time on the Mechanical Properties of Ultrafine Cemented Carbide

Tables 1 and 2 show the measured bending strength and hardness, respectively. It can be seen from the tables that both strength and hardness increase with the extension of ball milling time. As previously analyzed, the longer the ball milling time, the finer the WC grains in the sintered samples and the more uniform their distribution. This indicates that bending strength and hardness increase simultaneously with the refinement of grains. In the grain size range above the micron level, the strength and hardness of cemented carbide typically have an inverse relationship; that is, as bending strength increases, hardness decreases, and vice versa. However, in this case, both have improved simultaneously, which clearly shows that after high-energy ball milling, the obtained cemented carbide has reached the micro-nano scale grain size range. The hardness improvement of the cemented carbide in this study is very significant; generally, WC-10%Co has a hardness of about HRA91, but here it has reached as high as 92.8. This indicates that grain refinement has a very strong strengthening effect on cemented carbide.

???????

This paper has conducted a preliminary study on the relationship between ball milling time and grain size in WC-Co ultrafine cemented carbide, as well as the relationship between grain size and strength, hardness, and the following conclusions are drawn:

High-energy ball milling has a very strong breaking effect on WC grains, and the WC grain size refines with the increase of ball milling time. However, there is a critical point for the powder particle size during ball milling. Upon reaching this critical point, the grain size of the cemented carbide is the smallest, after which, with the increase of ball milling time, the grains may become coarser instead.

Micro-nano grain size cemented carbide can be obtained through high-energy ball milling, and the WC grains are more uniform and dispersed.

The refinement of the grain size of cemented carbide to the micro-nano scale can simultaneously increase the bending strength and hardness.