This article mainly introduces the installation and processing methods of cutting tools.

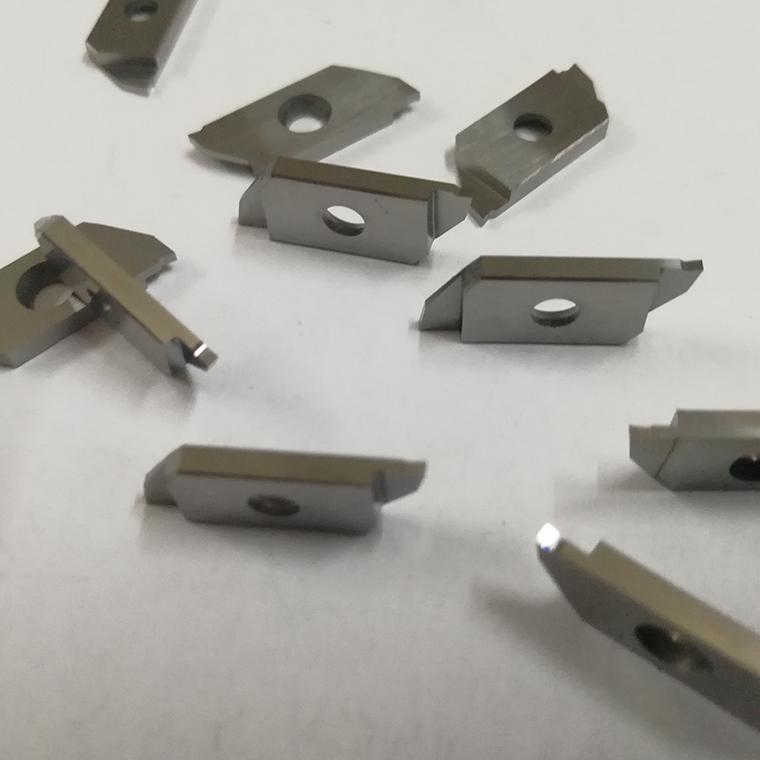

Grooving cutter has CNC grooving cutter, which is a tool used for cutting in mechanical manufacturing, also known as cutting tool.

The material of the knife has the following properties:

First, it has high hardness, and its normal temperature hardness is above HRC60.

Secondly, it has enough strength and toughness, enough bending strength and enough toughness to resist impact and vibration.

Third, high wear resistance. It has very high resistance to wear and can keep the blade sharp.

Fourth, high thermal hardness, which can maintain high hardness at high temperature.

Fifthly, good technology, easy to tool manufacturing and heat treatment.

According to the different equipment, the size of grooving cutter is also different. The function of slotting cutter is the same as that of many cutting tools, which is an essential cutting tool in mechanical manufacturing. Generally, it is used in some CNC lathe or CNC equipment. Of course, the use method of each slotting cutter is different. Let’s take an example.

For example, in CNC lathe slotting tool, it can not be lower than the center, the tool tip and the center of the workpiece the same height. In addition, when clamping the slotting tool, first of all, it should meet the general requirements of cylindrical turning tool clamping. The protruding part of the tool clamping on the tool holder should be as short as possible to enhance its rigidity. The number of gaskets should be as few as possible, and should be aligned with the edge of the tool holder. At least two screws should be used to compress them to prevent their vibration and produce bad use effect.

Of course, the size of slotting cutter should be consistent with the model of lathe. When the tip of the turning tool is higher than the axis of the workpiece, the actual back angle of the turning tool will be reduced, and there will be a very large friction between the back of the turning tool and the workpiece, which will shorten the tool life. If the tool tip is lower than the axis of the workpiece, the actual rake angle of the turning tool will decrease and the cutting resistance will increase. If the tool tip is not in the center, there will be a convex head when turning to the center of the end face. When using cemented carbide, if this point is ignored, turning to the center will cause the tool tip to break, so we must pay attention to it.

In addition, it is also necessary to pay special attention to that when clamping, the knife must not extend too long, and the center line of the knife must be perpendicular to the axis of the workpiece to ensure that the two secondary deflection angles are symmetrical, and the main cutting edge must be parallel to the axis of the workpiece; the bottom plane of the knife should be flat to ensure that the two secondary back angles are symmetrical. Therefore, it is very important to choose the size of slotting cutter.

Installation of external groove cutter

1. When the cutting tool can meet the processing requirements, the slotting tool should not extend too long during installation.

2. The height of the main cutting edge should be controlled within the range of 0 ± 0.2mm for the center of the workpiece when the groove is turned and the cross feed is carried out, and the height of the blade and the center of the workpiece should be as high as possible.

3. The blade shall be perpendicular to the center as far as possible, and the two secondary deflection angles shall be symmetrical to ensure that the main blade is parallel to the axis of the workpiece.

Installation of cutting tool

1. During installation, the cutter should not extend too long, and the center line of the cutter must be perpendicular to the center line of the workpiece, so as to ensure the symmetry of the two secondary deflection angles.

2. When cutting a solid workpiece, the main cutting edge of the cutter must be set at the same height as the center of the workpiece, otherwise it cannot be turned to the center, and it is easy to break the cutting edge or even break the turning tool

3. The bottom plane of the cutter should be flat to ensure the turning quality.

Processing method of straight groove outside car

1. When turning low and narrow grooves, the groove turning tool with the width equal to the groove width can be used, and the one-time straight forward method can be used.

2. For the groove with accuracy requirements, the two-step straight forward method is generally adopted.

Cut off method

1. Cut off the workpiece by straight forward method. The so-called straight forward method refers to cutting perpendicular to the axis of the workpiece. This method has high cutting efficiency, but it has high requirements for the grinding and installation of lathe and cutter, otherwise it is easy to break the cutter head.

2. Cut off the workpiece by the left and right knife method. In the case of insufficient cutting rigidity, the left and right tool borrowing method can be used to cut. Left and right borrowing method means that the cutter moves back and forth repeatedly in the axial direction, and then both sides feed radially until the workpiece is cut off.

3. Cut off the workpiece by reverse cutting. Reverse cutting method refers to the workpiece reverse, turning tool reverse clamping, this cutting method is suitable for larger diameter workpiece cutting.