The Concept of Metal Surface Treatment

It refers to the process of changing the surface condition and properties of parts and optimizing its combination with matrix materials to meet the predetermined performance requirements by using the edge new technologies of modern physical, chemical, metallurgy and heat treatment disciplines.

Classification of Metal Surface Treatment Technologies

1. Surface modification

The surface chemical composition of the material is not affected by changing the surface microstructure and stress state of the material.

2. Surface Alloying Technology

Adding new materials into the matrix to form alloying layer.

3. Surface film technology

Chemical reaction between additive and matrix to form conversion film

4. Surface Coating Technology

Common Metal Surface Treatments

Metal Surface Modification

Contains the following methods: surface hardening, sandblasting, knurling, wire drawing, polishing, laser surface strengthening

Metal Surface Hardening

It refers to a kind of heat treatment method that austenitizes the surface layer and cools it rapidly without changing the chemical composition of the steel, so as to harden the surface.

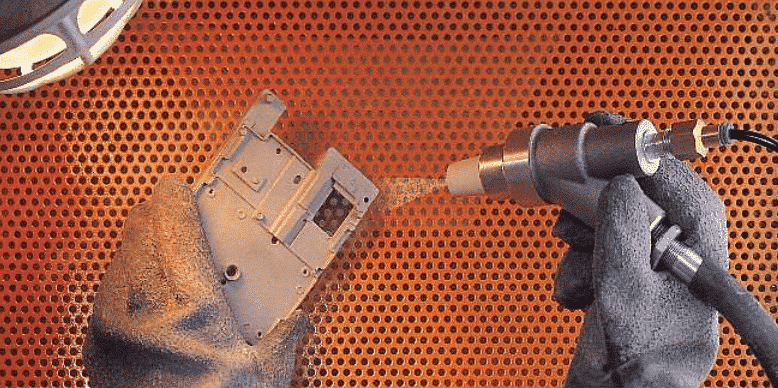

Metal Surface Sandblasting

The surface of workpiece is impacted by high-speed sand and iron particles, which is used to improve part mechanical properties and change surface state. This operation can effectively improve mechanical strength, wear resistance, and eliminate residual stress.

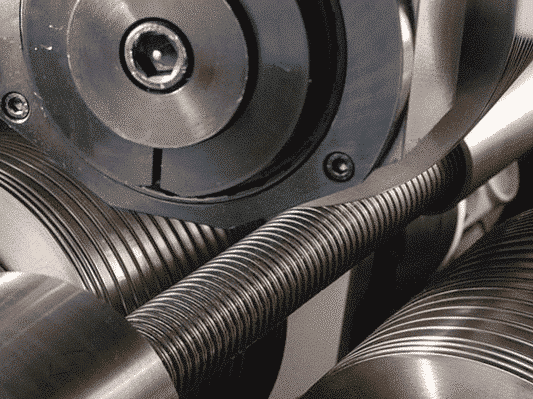

Metal Surface Rolling

It is to press the surface of the workpiece with a hard roller at room temperature so that the surface of the workpiece can be hardened by plastic deformation to obtain an accurate and smooth surface.

Wire Drawing of Metal Surface

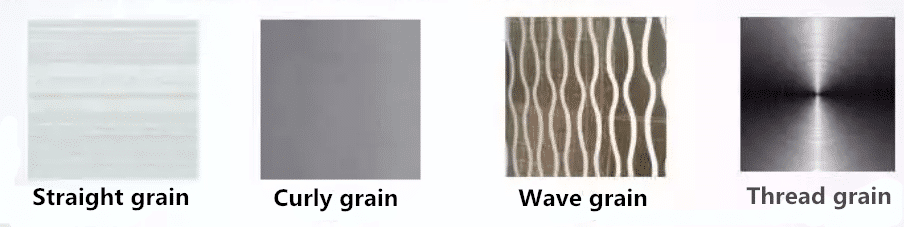

Under the action of external force, the metal is forced through the die, and the cross-sectional area of the metal is compressed so as to change its shape and size. The method is called wire drawing. Wire drawing can be made into several kinds of threads, such as straight, curly, wave and threaded, according to decorative requirements.

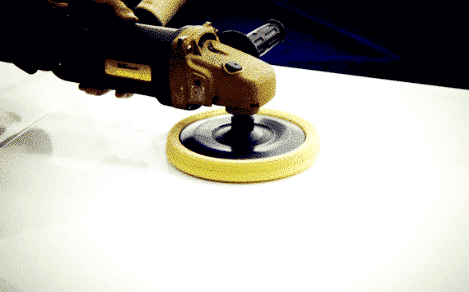

Metal Surface Polishing

Polishing is a finishing method to modify the surface of parts. It can only get smooth surface without improving the processing accuracy. The Ra value of polished surface can reach 1.6-0.008 um.

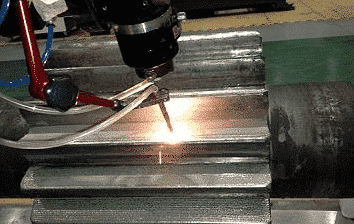

Metal Surface Laser Strengthening

A focused laser beam is used to heat the workpiece rapidly and then rapidly cool the workpiece to obtain a hardened and strengthened surface. Laser surface strengthening has the advantages of small deformation, easy operation, and local strengthening.

Metal Surface Alloying Technology

By physical methods, the additive material is added into the matrix to form an alloying layer. Common carburizing and nitriding belong to this kind of technology. It makes the metal and the Infiltrator placed in the same sealed chamber, activates the metal surface by vacuum heating, and makes carbon and nitrogen enter the metal matrix in the form of atoms to achieve the purpose of alloying.

Blackening and Phosphating of Steel Metal Surface

Blackening: Black or blue oxide film is produced to insulate the air from corrosion of the workpiece.

Phosphating: An electrochemical metal surface treatment method for protecting the base metal by depositing a clean phosphate insoluble in the water on the surface of the workpiece immersed in phosphating solution.

Both of them do not affect the internal structure of the workpiece. The difference is that blackening of iron and steel will make the workpiece shiny, while phosphating will increase the thickness of the workpiece surface and make the surface dull. Phosphating is more protective than blackening. Blackening is generally more expensive than phosphating in terms of price.

Metal Surface Coating Technology

The layer of coating or coating is formed on the surface of the substrate by physicochemical method. This is widely used in cemented carbide tools.

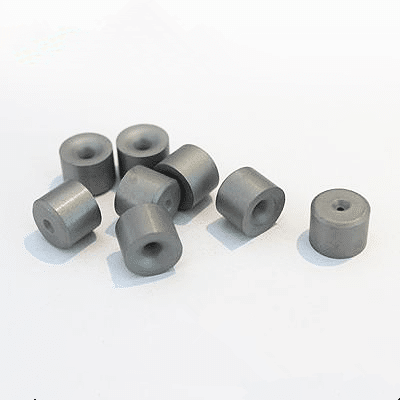

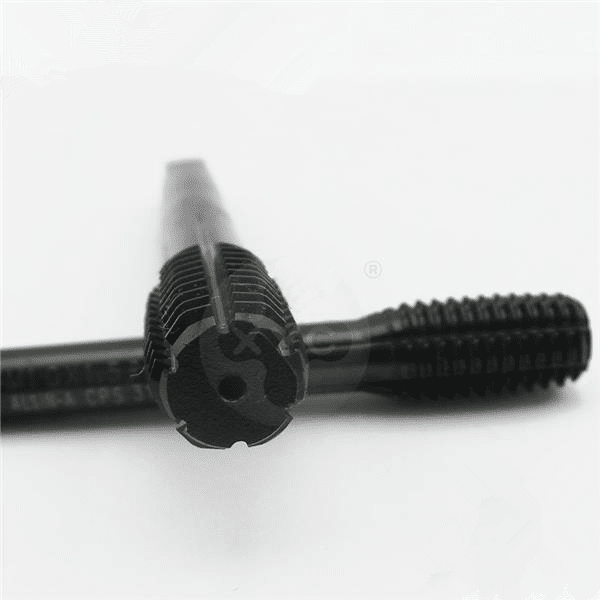

TiN Coating and TiCN Coating on Metal surface

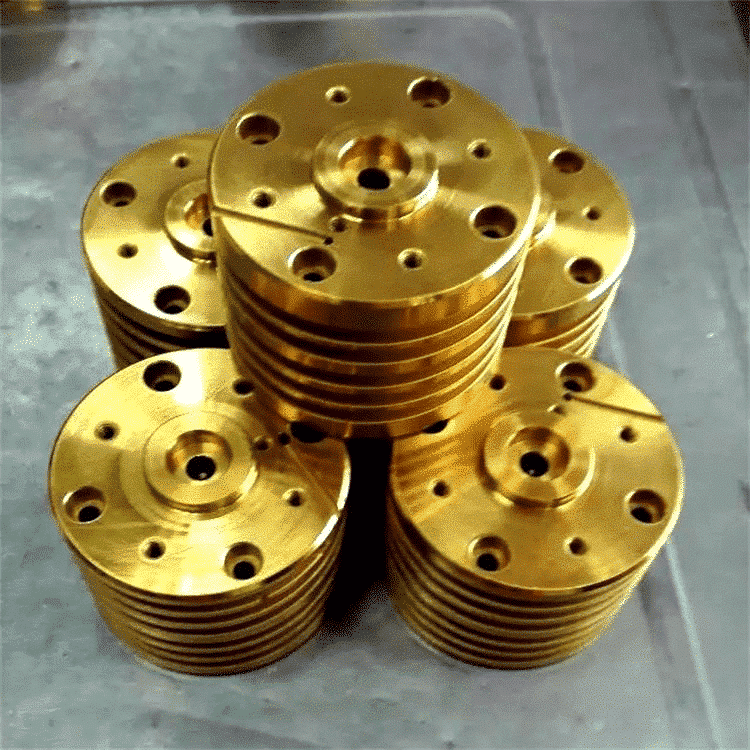

A few microns thick TiN material is usually golden on the cutting tool for cutting softer copper or low carbon steel.

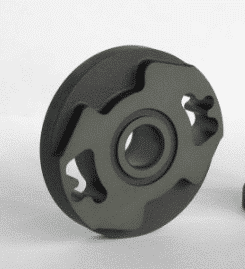

Black TiCN coatings are mostly used in occasions with small friction coefficient but high hardness requirements.

Above is our brief introduction of metal surface treatments. If you have more information about this topic, please leave a message below to discuss with us.